Laser vs Dot Peen Marking Machines: Direct Part Marking By Industry

When every part counts, every mark matters.

In industries where traceability, compliance, and durability are non-negotiable, direct part marking ensures critical information stays where it belongs — on the part itself. Whether you’re tracking components through a supply chain, meeting regulatory standards, or branding products for longevity, the right marking method can make all the difference.

Two technologies dominate the world of part marking: laser marking machines and dot peen marking machines. While both offer reliable solutions, their strengths shine in different applications. From the precision demands of the medical and electronics industries to the rugged requirements of the automotive and energy sectors, choosing the right solution depends on your materials, environment, and production needs.

Let’s explore how laser part marking and dot peen marking perform across key industries, highlighting the best use cases for each technology.

What is Direct Part Marking?

Direct part marking refers to the process of permanently engraving or imprinting information — such as serial numbers, barcodes, or logos — onto a part. This process is essential for industries requiring traceability and identification throughout a product’s lifecycle.

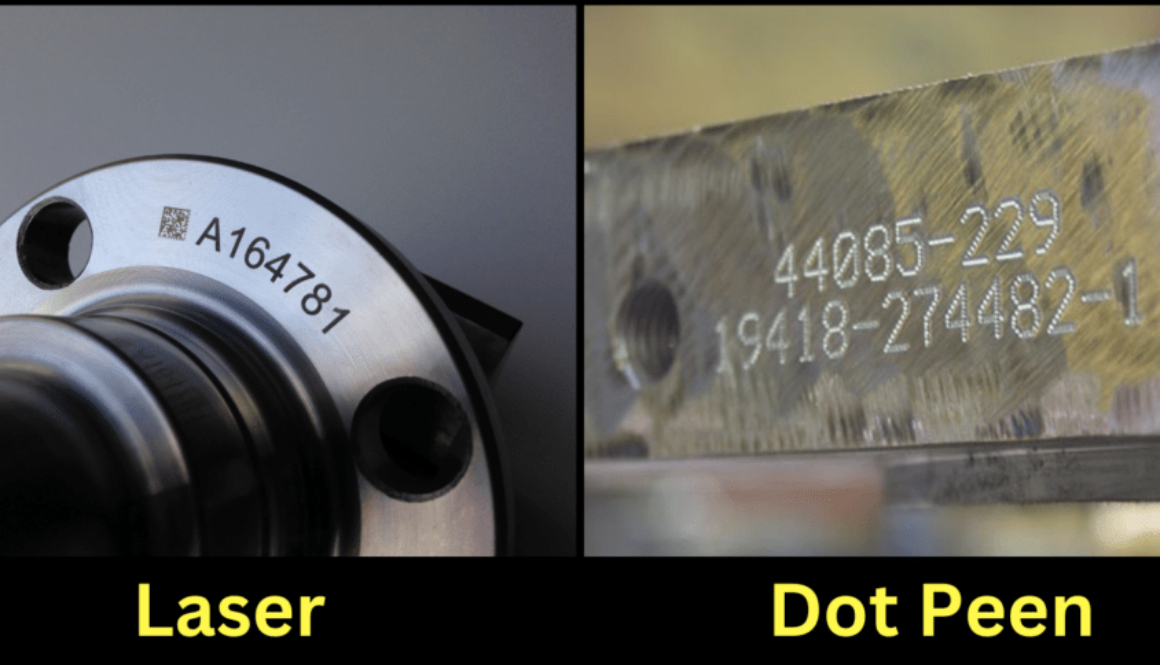

Laser Part Marking: An Overview

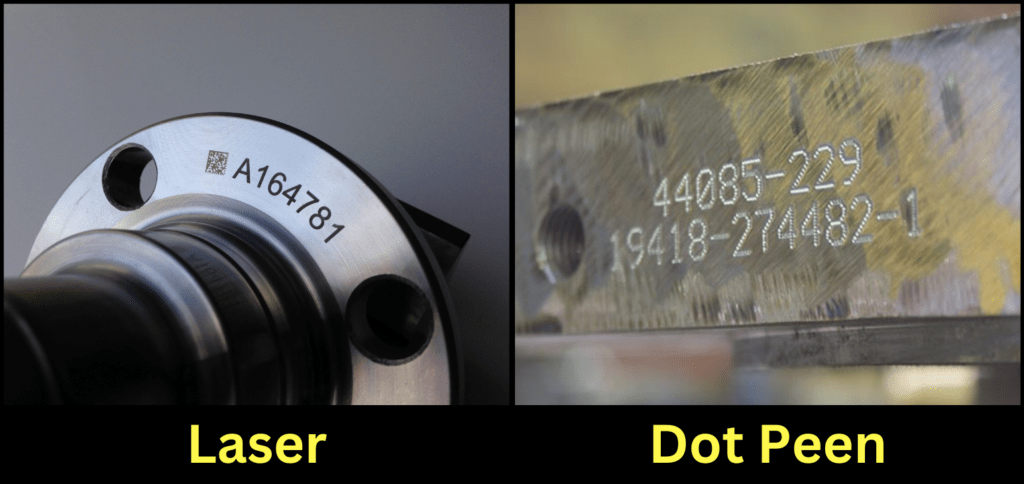

A laser marking machine uses a focused laser beam to mark materials precisely. This non-contact method doesn’t physically alter the surface, making it ideal for fragile or thin materials.

Advantages of Laser Marking:

- Precision: High detail, capable of marking tiny, complex designs.

- Material Versatility: Works on metals, plastics, ceramics, and more.

- Durability: Marks are resistant to wear, corrosion, and environmental damage.

- Non-Contact: Ensures no stress or damage to the part.

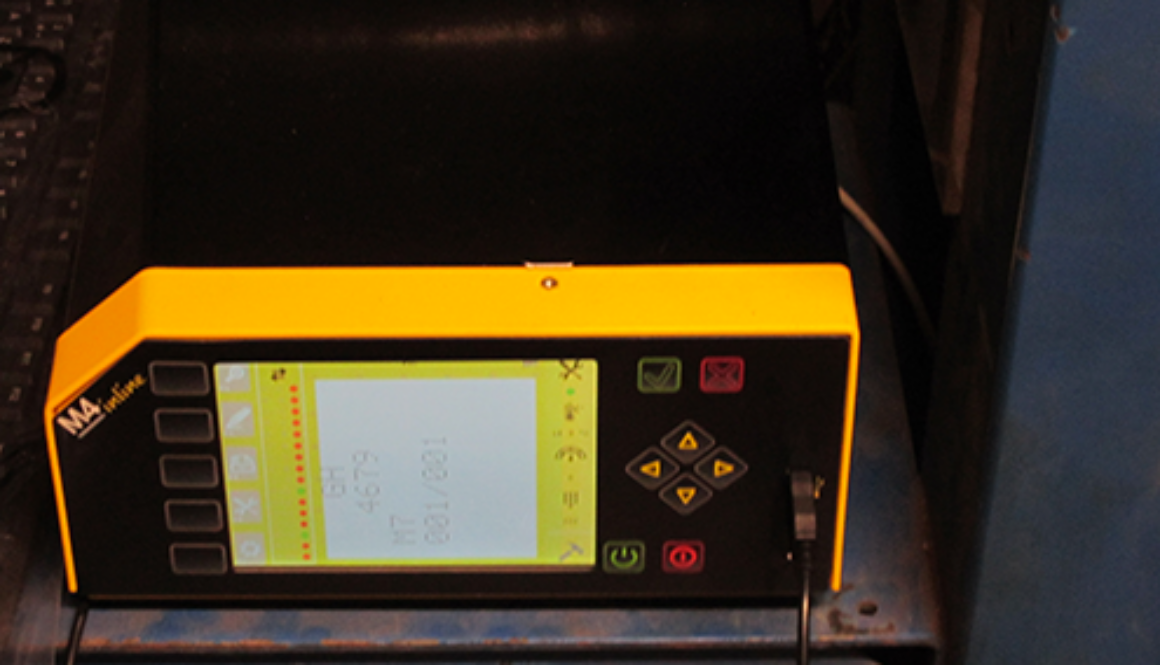

Dot Peen Marking Machines: An Overview

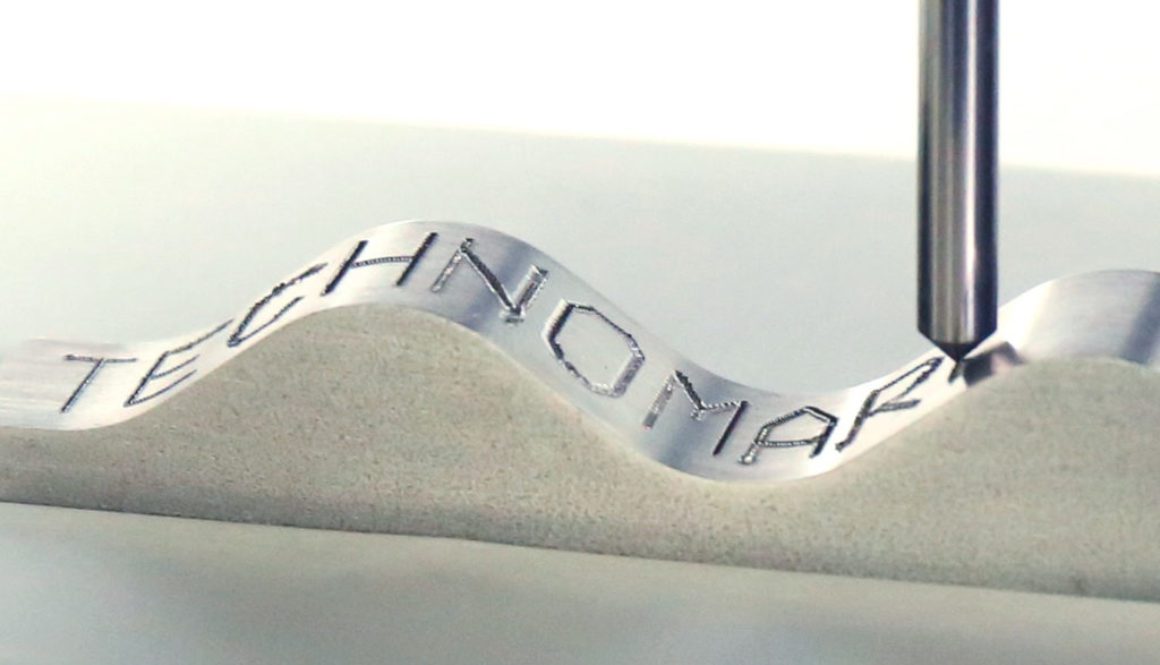

A dot peen marking machine creates permanent marks by using a stylus that rapidly strikes the material, forming a series of dots. This mechanical process is efficient for deep and rugged markings.

Advantages of Dot Peen Marking:

- Durability: Deep marks withstand extreme conditions, ideal for rough handling.

- Cost-Effective: Lower operating costs compared to lasers.

- Material Compatibility: Works well on metals and other hard surfaces.

- Speed: Fast marking process, especially for serial numbers or codes.

5 Factors to Consider When Choosing Between Direct Part Marking Methods

The choice between laser marking systems and dot peen marking machines often comes down to the specific application and the amount of material impacted during the marking process. Industries like medical, automotive, and defense rely on both technologies, selecting the best method based on their unique marking needs and the materials being marked.

When deciding between laser marking and dot peen marking for your production processes, consider these five key factors:

1. Specific Industrial Application Needs

- Detail Requirements: Consider the level of detail required in the mark, including font size, complexity of logos or barcodes, and the need for high-resolution images.

- Mark Durability: Determine the level of resistance required to factors like abrasion, chemicals, and extreme temperatures.

2. Material Types and Properties

- Material Compatibility: Evaluate the marking method’s suitability for different materials, considering factors like hardness, heat sensitivity, and surface characteristics.

- Mark Aesthetics: Assess the desired appearance of the mark, such as the smoothness, depth, and contrast.

3. Operating Environment

- Environmental Conditions: Consider factors such as temperature fluctuations, exposure to dust or debris, and the presence of corrosive substances.

- Production Line Integration: Determine the need for integration with existing production lines and automation systems.

4. Production Volume

- Throughput Requirements: Evaluate the required marking speed and the need for high-volume, automated marking solutions.

5. Regulatory and Compliance Requirements

- Industry Standards: Ensure the chosen method complies with relevant industry standards and regulations, such as those in the aerospace, automotive, or medical device sectors.

Making the Right Decision: Steps to Choose the Suitable Direct Part Marking System

Selecting the right marking system for industrial applications involves evaluating key factors to ensure it meets both current demands and future requirements. The right choice will align with industry standards, optimize efficiency, and deliver a strong return on investment.

Here are three essential steps to guide your decision:

- Consult with marking system experts

- Consider future scalability and adaptability

- Test and sample potential systems

1. Consult with Marking System Experts

Partnering with marking system specialists can provide critical insights to streamline your decision-making process. These experts can:

- Offer in-depth knowledge of the latest technologies and their capabilities.

- Evaluate your specific needs to match them with the strengths and limitations of different marking systems.

- Share real-world examples and case studies from similar industrial applications, showcasing solutions to common challenges.

- Advise on total cost of ownership, including ongoing maintenance, consumables, and potential system upgrades.

2. Considering Future Scalability and Adaptability

Choosing a marking system that aligns with your business’s long-term goals is essential for ensuring sustained efficiency and performance. A well-chosen system should not only meet your current needs but also support future growth with the following qualities:

- Scalability: Opt for a system capable of handling increased production volumes or extended operational hours without compromising quality or causing significant downtime.

- Adaptability: Ensure the system is versatile enough to mark new materials, accommodate different part geometries, or meet evolving marking requirements as your product lines expand.

- Software and Integration: Look for systems with upgradable software that offer new features and ensures compatibility with emerging technologies. Seamless integration with your existing production management or quality control systems is also key.

3. Test and Sample Potential Systems

Before committing to a marking system, conducting thorough testing is essential to ensure it meets your production and quality requirements. This process should include:

- Sample Marking: Share samples of your materials with manufacturers or distributors and request marking demonstrations. Evaluate the results for quality, speed, precision, and material compatibility.

- On-Site Demonstrations: Whenever possible, arrange on-site demos to observe the system’s performance in your actual production environment, including workflow integration and operator ease of use.

- Durability Testing: Assess the longevity of the marks by exposing them to conditions that replicate your operational environment, such as chemicals, abrasives, and wear over time.

Request a Demo

Laser Marking vs. Dot Peen Marking Machines: Industry-Specific Applications

From automotive to agriculture and beyond, industries that rely on permanent product identification share a common need: marks that are reliable, readable, and durable. Whether it’s for lifespan management, traceability, or recall processes, the marking method must align with each industry’s unique demands.

In some sectors, the ability to withstand extreme wear, corrosion, or heat is paramount. In others, the priority is minimizing surface disruption while maintaining clarity and precision.

Choosing the right marking system depends on these priorities. The chart below highlights the key benefits of laser marking systems and dot peen marking machines across various industrial applications, helping you determine the most effective solution for your products.

| Industry | Dot Peen Use | Laser Marking Use |

| Aerospace | ||

| Medical | ||

| Automotive | ||

| Defense |

Industry Specifications: Determining the Right Marking System

Direct part marking is no longer just a requirement; it’s a strategic advantage. Whether you need the precision of a laser marking system for delicate medical instruments and electronics or the rugged reliability of a dot peen marking machine for aerospace and automotive components, the right technology ensures that your marks remain permanent, readable, and resilient.

Looking for more industrial applications? Take a look at our Industrial Applications page.

Ready to Take Direct Part Marking to the Next Level?

Learn how laser marking’s precision, versatility, and durability can elevate your manufacturing processes. Visit our Laser Marking Page to explore how Technomark’s cutting-edge solutions can meet your industry’s marking needs.

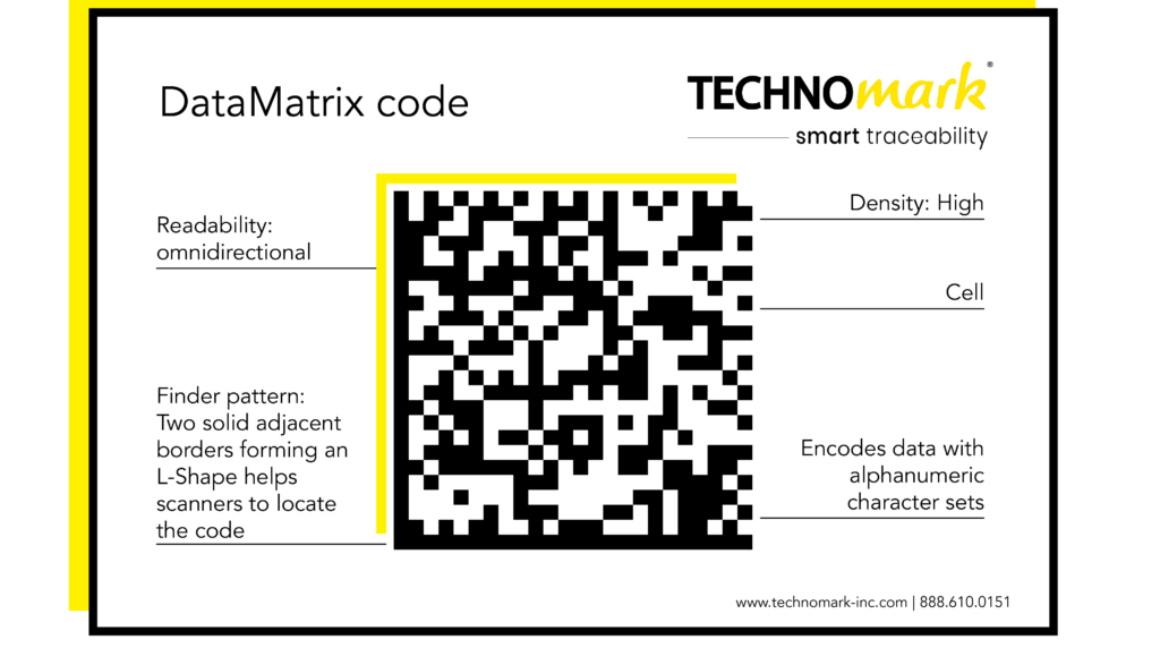

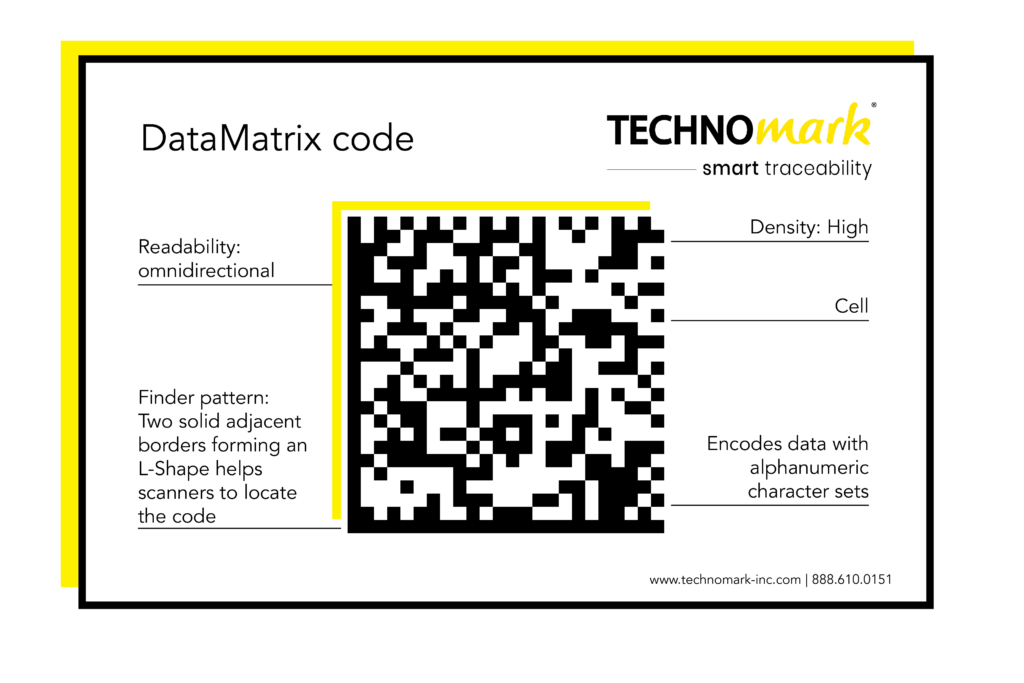

Data Matrix codes are another type of two-dimensional barcode, but they are smaller and more compact than QR codes. They are often used in industrial settings, such as manufacturing and logistics, because they are highly durable and can be scanned even when damaged or dirty. Data Matrix codes are useful for tracking individual items or components throughout production, ensuring accuracy and efficiency.

Data Matrix codes are another type of two-dimensional barcode, but they are smaller and more compact than QR codes. They are often used in industrial settings, such as manufacturing and logistics, because they are highly durable and can be scanned even when damaged or dirty. Data Matrix codes are useful for tracking individual items or components throughout production, ensuring accuracy and efficiency.

Laser marking wins in precision and detail, making it preferable for industries requiring intricate designs or small text. It is considered ideal for barcodes, UID codes, QR codes, and detailed logos.

Laser marking wins in precision and detail, making it preferable for industries requiring intricate designs or small text. It is considered ideal for barcodes, UID codes, QR codes, and detailed logos.