Types of Laser Marking: How to Choose the Best Laser for Your Needs

Choosing the right laser marking tool can be overwhelming, especially with the numerous laser technologies and marking options available. From fiber laser sources to CO₂ and green lasers, each has its strengths, and your choice directly impacts the quality of marking, material compatibility, and the long-term success of your operation.

If you’re working in industrial laser marking, whether you’re an engineer, a production manager, or a manufacturing professional, it’s essential to know what matters most for your application.

Are you seeking deep, durable marks that meet stringent regulatory standards, or is speed and precision your top priority?

Each type of laser marking offers unique advantages depending on your goals, and making the right choice starts with understanding your options.

We’ll break down the different types of laser marking, including three primary laser technologies and two key subtypes. As well as how to select the best laser marking source for your specific needs, with tips on choosing the right material and achieving the required marking depth for compliance and optimal performance.

5 Types of Laser Marking Based on Wavelength

Laser part marking is a standard practice in several industries due to its effectiveness in long-term part identification and its compliance with the rigorous standards set forth for aerospace, mechanical, and other high-demand sectors.

However, each industry has specific needs regarding the product, as well as potential damage that can occur if the wrong laser is used. The equipment you need is just one part of the process; however, first, you’ll want to consider which laser is best suited for your application.

There are five standard lasers for laser marking:

- CO2 laser

- Fiber laser

- YAG laser

- Green laser

- UV laser

1. CO2 Laser

CO2 laser marking is a popular laser engraving and marking solution because of its ability to mark non-metallic materials. It’s efficient in marking a variety of non-metals, too, including:

- Wood

- Plastic

- Glass

- Textiles

- Cardboard

The CO2 laser produces an infrared laser beam and uses CO2 gas as the active medium. The laser is emitted at 10.6 micrometers and features high beam quality, allowing it to focus laser power into a small spot and produce high-quality laser marks. This laser has the longest wavelength, which falls within the invisible infrared spectrum.

This laser is efficient for cutting some materials and for personalizing products. However, this type of laser also requires more maintenance and uses more energy.

2. Fiber Laser

Another laser source is fiber laser marking, which also enables the accurate marking of non-metallic surfaces. The fiber laser source operates at a shorter wavelength than a CO2 laser, utilizing a fiber optic laser device to emit laser beams at a wavelength of 1.064 micrometers. The wavelength produced falls within the infrared spectrum.

It quickly and accurately produces laser marks on materials such as:

- Plastics

- Metals

- Rubber

- Glass

This laser source also offers the ability to be tuned for specific applications with easily adjustable settings.

A fiber laser can also be used for embossing or to add discoloration where desired. The discoloration process with a fiber laser offers a range of colors and improved control simultaneously.

The fiber laser is the most commonly used in the laser marking industry, particularly common in aerospace, metallurgy, automotive, and mechanical applications. It’s helpful for all types of metals and has a longer lifespan compared to other lasers.

3. YAG Laser

The YAG laser operates at a wavelength similar to that of the fiber laser (1.064 micrometers). However, this type of laser has a different structure from a fiber laser, and the beam passes through multiple crystals to create the beam.

The YAG laser is ideal for marking metals and plastics in its more widely recognized configuration. However, it can also be adjusted to mark more sensitive materials.

4. Green Laser

The green laser, the first subtype of the YAG laser, is the only laser with a wavelength in the visible spectrum. This allows manufacturers to mark many sensitive materials, such as:

- Polymers

- Plastics

- Rubber

The green laser is ideal for these sensitive materials because its wavelength is located near the UV spectrum, which generates less heat.

5. UV Laser

The UV laser is another subtype of the YAG laser. Thanks to implanted crystals, it became possible to adjust the wavelength for this laser and utilize others, providing access to the only laser in the invisible ultraviolet spectrum (0.355 micrometers).

The UV laser has the shortest wavelength used in the laser marking field and, as such, is relied upon for markings on fairly sensitive materials.

This laser also enables the execution of “cold markings”, allowing manufacturers to avoid part degradation due to heat. This laser is used for marking solar panels, electrical components, and other parts that require a refined approach.

6 Ways to Choose a Laser Marking Source

Planning the production of your next line involves numerous considerations. These include the materials you will use and the expected completion time for products.

Meanwhile, several of those factors also influence the choice of laser:

- Material to be marked

- Mean time between failures (MTBF)

- Depth of mark needed

- Laser maintenance needs

- Speed of the marking process

- Ease of settings adjustment

1. Material to be Marked

With the variety of materials used in production, it makes sense to prioritize the materials when considering a laser source. For more heat-sensitive materials, it is important to find the right laser and access one that is easily adjustable.

2. Mean Time Between Failures (MTBF):

The Mean Time Between Failures (MTBF) is a measure of the reliability of your laser based on its operating hours. Each laser has a different expectation, and please note that these are average times, not guaranteed lifespans. Some lasers have a longer MTBF but can fail in a shorter period than expected.

While the fiber laser has a Mean Time Between Failures (MTBF) of 100,000 hours, CO2 lasers have a significantly shorter MTBF of 30,000 hours. This is a crucial factor to consider when selecting the best option for your production cadence.

3. Depth of Mark Needed

Some lasers are singled out for the ability to make deeper marks than others. For specific regulations and standards, the laser with a deeper marking capability would be the preferred choice.

Meanwhile, other materials require a lighter mark that doesn’t cause damage. Therefore, the depth of the mark is a significant factor in selecting a laser source.

4. Laser Maintenance Needs

Some lasers require more maintenance than others. This means a commitment of more of the budget and possible interference with production timelines if maintenance is needed frequently.

5. Speed of Marking Process

Your production timeline is important for both your revenue and to help your clients meet their own projected deadlines. As such, the marking process needs to be completed promptly.

Note: Depending on the material to be marked, the correct laser source can significantly impact meeting the timeline and avoiding delays caused by lengthy marking processes.

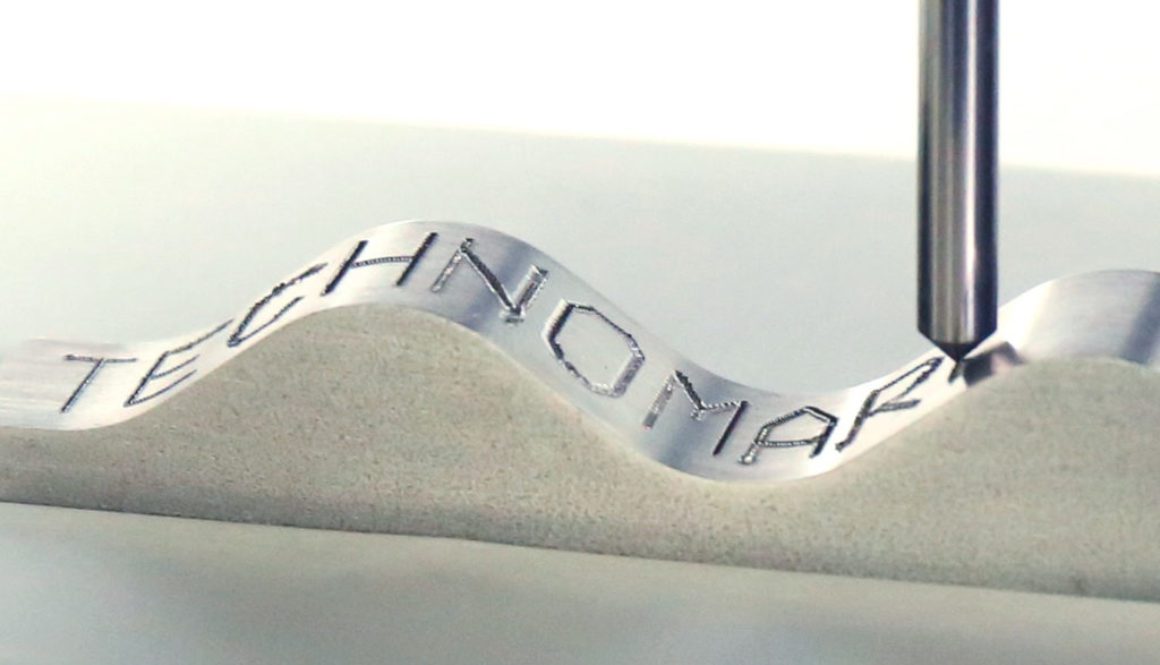

Resource: If laser marking isn’t the answer at all, there’s always dot peen marking.

6. Ease of Settings Adjustment

In some industries, the laser will need to be adjusted for separate part lines or stages in the production process. In such cases, it is more cost-effective to find a laser that can be easily adjusted. This facilitates effective marking on the desired timeline more effectively.

Which Laser Marking Source is Right for Your Production Needs?

With three laser marking types and two subtypes, it should be a reasonable process to narrow down the best laser for an application based on the factors involved. Your production line requires a specific type of mark, and you expect how long that mark will last.

The right laser marking source means faster delivery of products that carry distinct markings to fit your clients’ needs.

Don’t Waste Money and Lose Project Momentum

If you have questions about the right laser source for your project, it’s time to talk to our experienced Technomark staff. Reach out today, and we can help point you in the right direction.

(Editor’s note: This blog was originally published in January 2023 and was updated recently to reflect the most up-to-date information.)

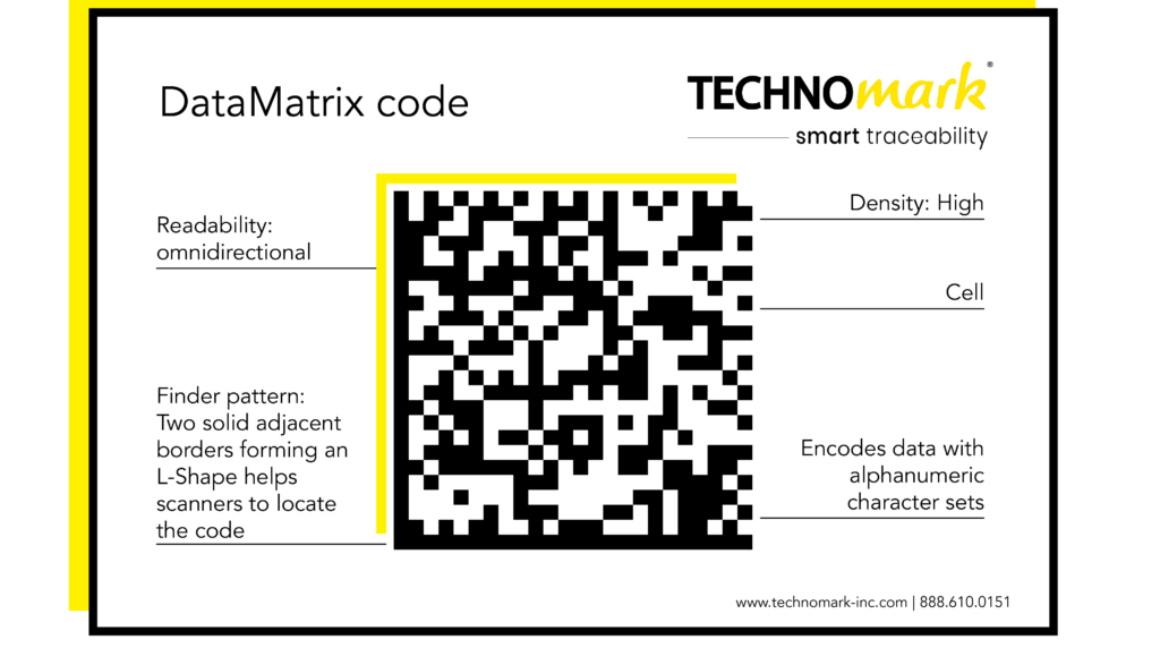

Data Matrix codes are another type of two-dimensional barcode, but they are smaller and more compact than QR codes. They are often used in industrial settings, such as manufacturing and logistics, because they are highly durable and can be scanned even when damaged or dirty. Data Matrix codes are useful for tracking individual items or components throughout production, ensuring accuracy and efficiency.

Data Matrix codes are another type of two-dimensional barcode, but they are smaller and more compact than QR codes. They are often used in industrial settings, such as manufacturing and logistics, because they are highly durable and can be scanned even when damaged or dirty. Data Matrix codes are useful for tracking individual items or components throughout production, ensuring accuracy and efficiency.

Laser marking wins in precision and detail, making it preferable for industries requiring intricate designs or small text. It is considered ideal for barcodes, UID codes, QR codes, and detailed logos.

Laser marking wins in precision and detail, making it preferable for industries requiring intricate designs or small text. It is considered ideal for barcodes, UID codes, QR codes, and detailed logos.