TECHNOMARK North America offers various integrations for both Dot Peen and laser marking equipment.

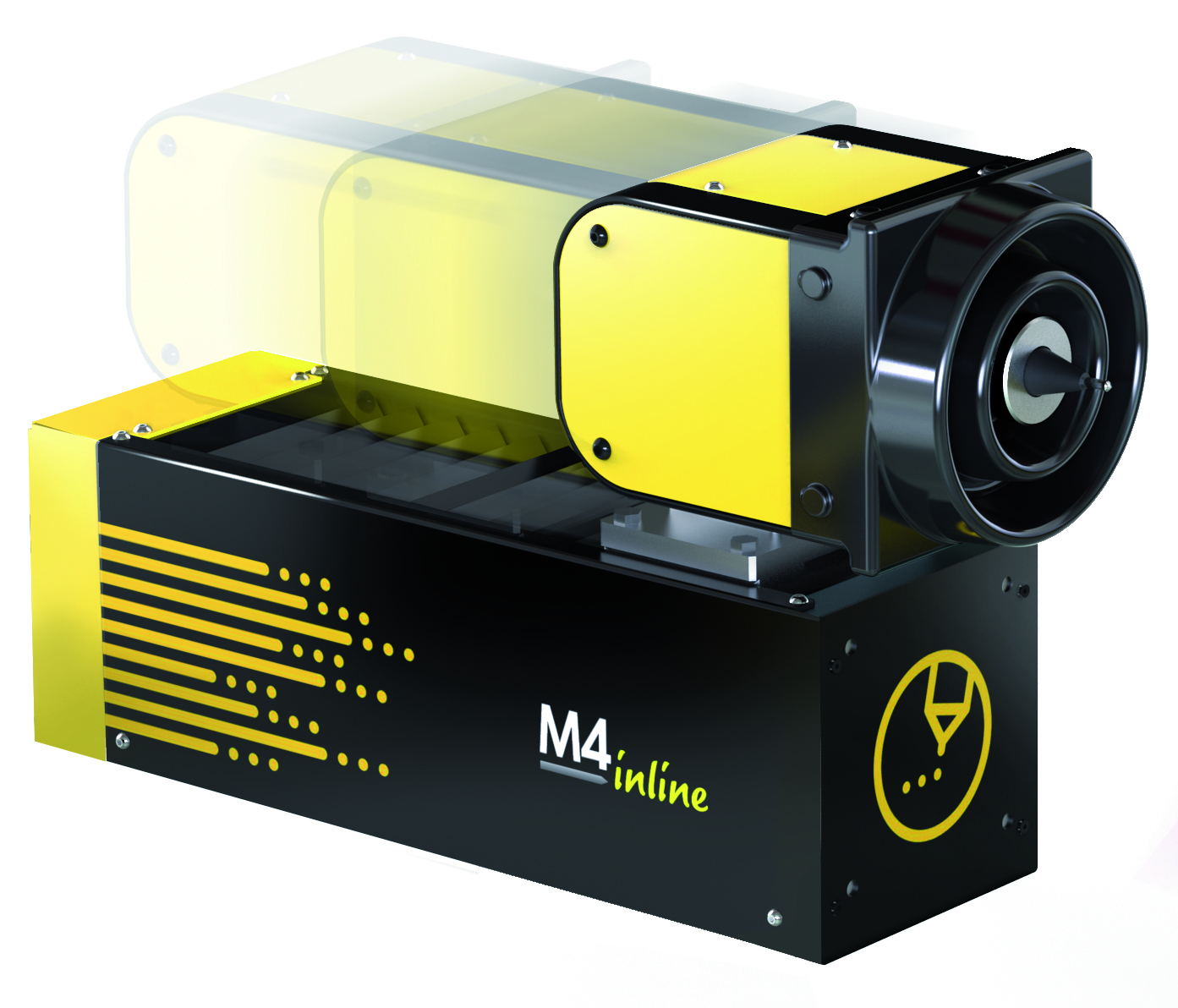

Integrated Solutions for Laser Marking Systems

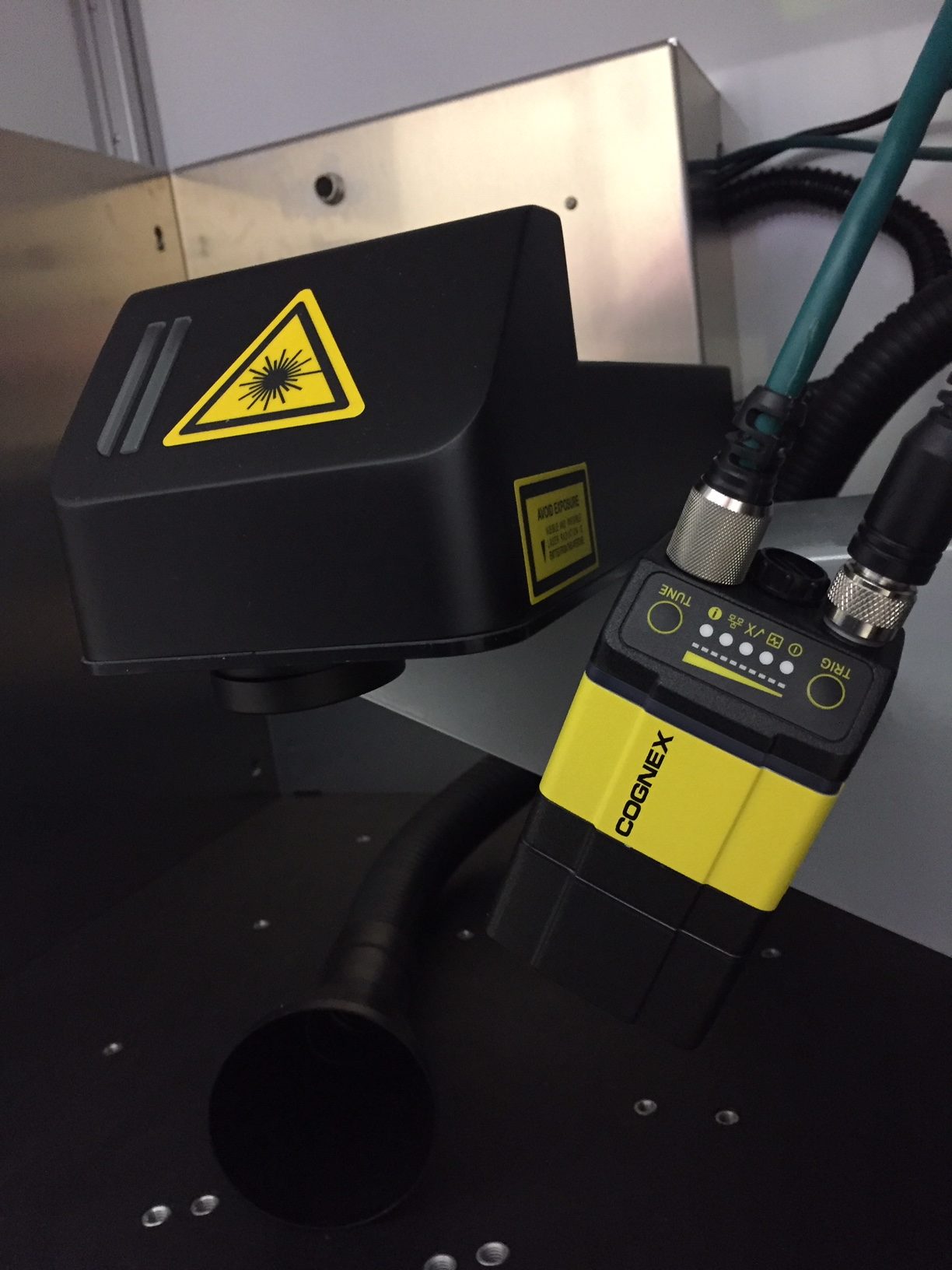

- Technomark has partnered with Cognex to develop an integrated barcode reader package for the Graphix laser marking workstation.

- The DataMan 370 series fixed-mount barcode readers solve challenging direct part mark applications with advanced decoding algorithms, integrated lighting, and auto-focus liquid lens technology.

- The fixed-mount barcode readers are available as an upgrade with the standard Graphix laser marking system to make your laser marking processes more efficient. This all-in-one solution lowers your total cost of ownership (TCO) by integrating a 2D data matrix and QR code reader into your production line, eliminating the need for another identification system.

Custom Tooling Solutions

- Technomark North America has partnered with IDEX Corp. to provide a marking solution for permanent identification of BAND-IT metal ID bands in a high-volume production environment.

- BAND-IT colored bands are used for frac iron recertification, asset management, and other visual identification programs. BAND-IT COLOR-IT® technology resists weathering and color fading, with 16 stocked colors available for same-day delivery and custom powder coating available for non-standard colors. BAND-FAST® preassembled band and clips allow for a safe, quick installation.

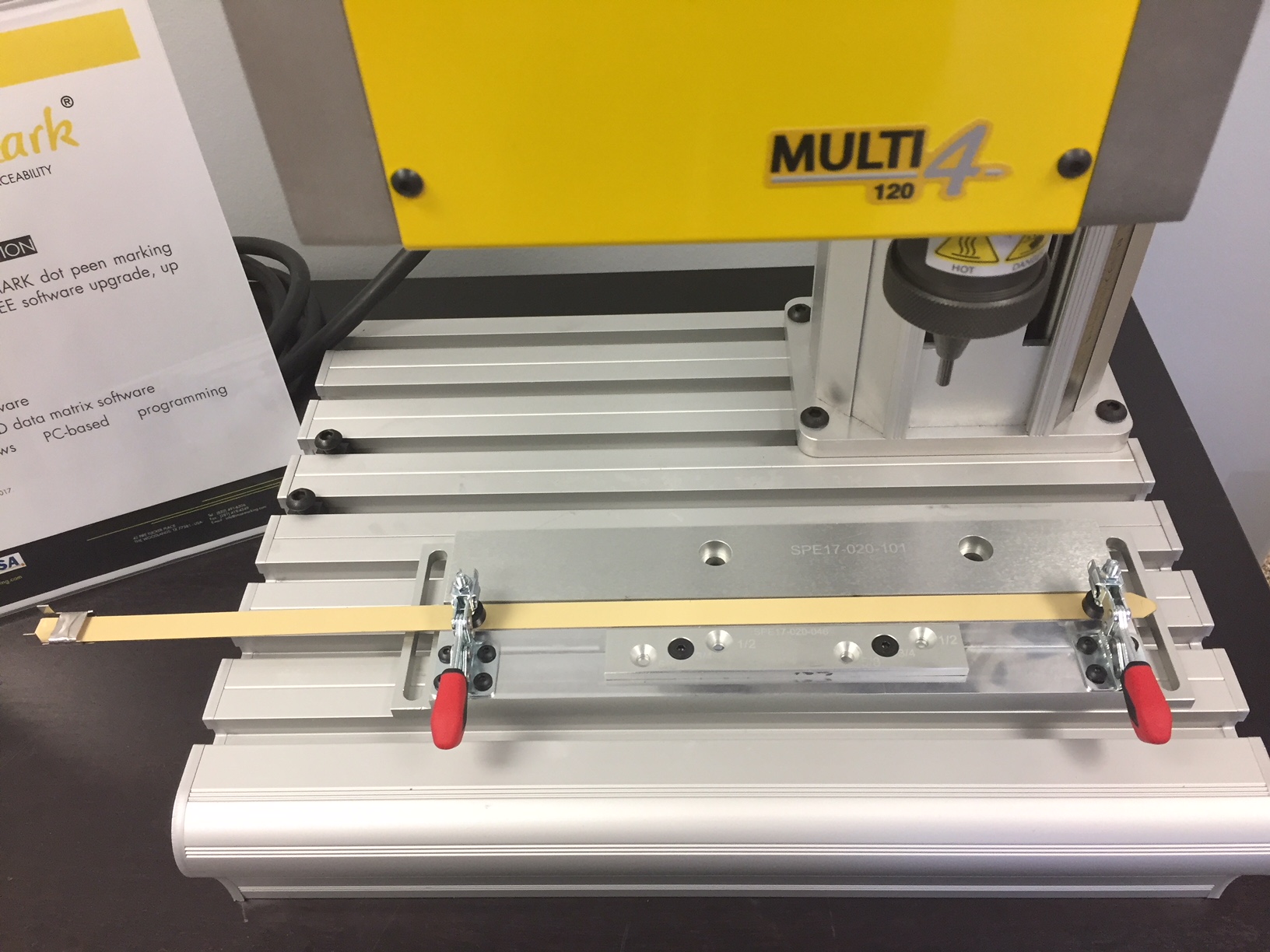

BAND-IT integrations are available for the

- Multi4 dot peen marking system — 1-up BAND-IT metal ID band loading fixture

- Graphix laser marking workstation — 3-up BAND-IT metal ID band loading fixture

Manufacturing Automation Solutions

Technomark North America has partnered with SLINED Automation & Robotics to provide manufacturing automation solutions specifically designed to meet your process requirements. Custom engineered solutions from SLINED reduce manufacturing cost, increase productivity, and save time and money. Whether you need a one-piece fixture or a complete automatic machine, SLINED offers full in-house integrated capabilities to satisfy your requirements.