Industrial Marking Materials

Dot Peen Marking, Laser Marking & Appropriate Materials

Properties for materials can vary depending on:

- Surface treatment

- Composition

- Overall condition

Therefore, testing and verifying the marking results is important prior to using a specific process for industrial purposes. Some of the most common materials that have been tested and shown success for industrial marking include aluminum, brass, copper, titanium, stainless steel, steel, some plastics, rubber, and some composite materials.

Parameters for the possibility of marking a material

The potential to permanently mark a material takes a number of factors into consideration, including:

- Chemical composition: The material’s response to an established marking process

- Hardness: The material’s ability to be marked using specific techniques, such as micro-percussion

- Breaking limit: Whether or not the material is resistant to marking from the stylus and the level of tolerance of marking (i.e. micro-percussion)

- Surface: This includes both treatment and whether the material has a smooth surface or not

- Temperature: The material’s ability to be exposed to high temperatures and its subsequent reaction

Learn more about your specific materials and the right industrial part marking solution.

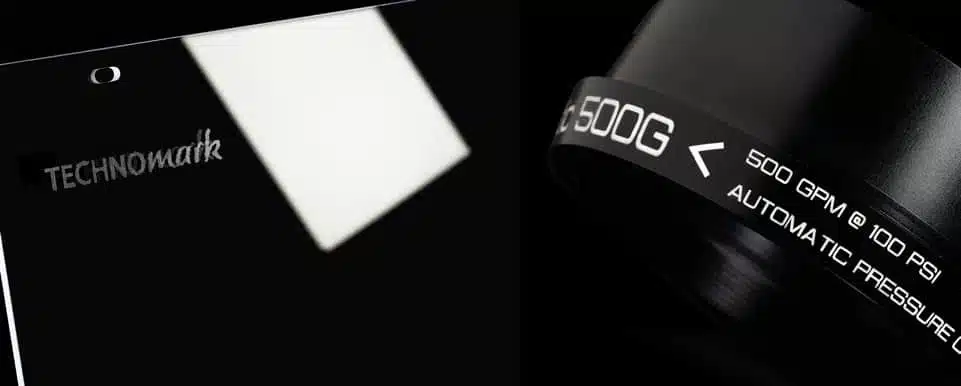

Plastic Marking

Plastics are now commonly used in all types of industries and for all types of parts. Technomark Marking can carry out laser engraving and micro-percussion engraving on the following types of plastics.

Marking on plastics offers many advantages, including:

- Resistance to abrasion, chemicals and temperature variations

- Long-term legibility of the marked information

- High precision (in terms of laser marking) with a professional and attractive aesthetic for your products

Our team of experts will be happy to advise you on the best marking technology for your specific material and application needs.

Steel Marking

Steel is a widely utilized metal alloy, primarily composed of iron and a small percentage of carbon. It is this carbon content, however minute, that bestows steel with its unique properties.

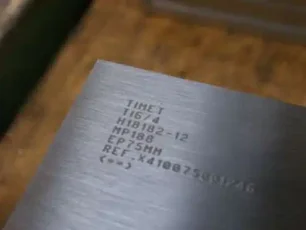

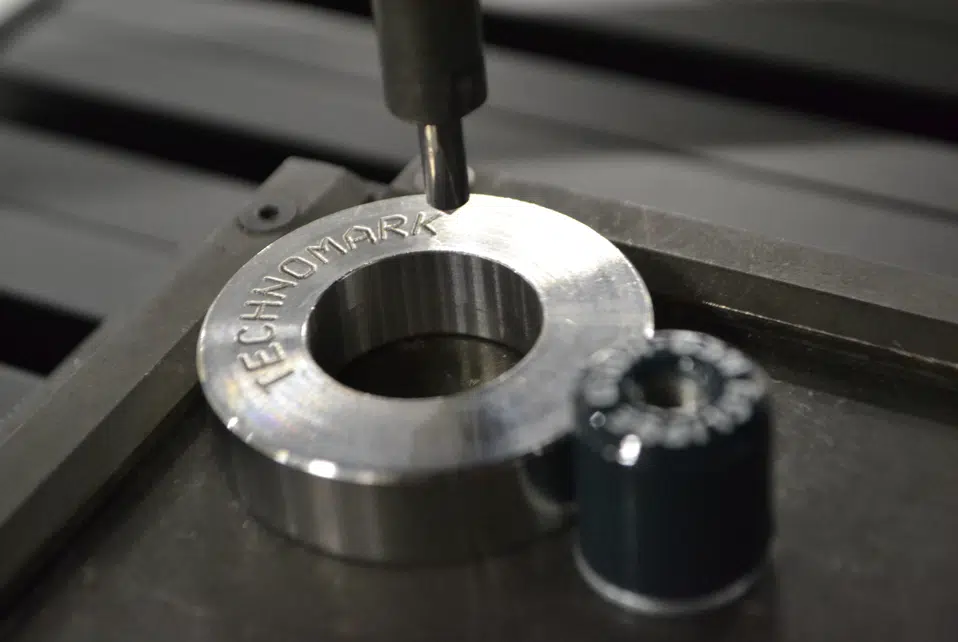

The production of steel is tailored to meet specific needs, and its composition enables it to withstand various mechanical or chemical stresses. Technomark Marking offers laser and dot peen marking services on steel components without altering their inherent properties. Depending on the steel alloy, marking can range from surface engraving to deep engraving. Additionally, certain steel types, particularly stainless steels, can undergo annealing, a highly specialized and superficial marking process that allows for coloration.

Mechanical engraving is a prevalent practice in industries, and steel remains the most widely utilized metal across numerous sectors. Numerous engraving techniques and tools have been employed for a substantial period to mark steel. Traditionally, stamps were used for industrial marking, but modern engraving machines have streamlined the process, making it more efficient and precise, resulting in sharper and more accurate permanent markings.

Aluminum Marking

Aluminum is a versatile and widely used metal, known for its malleability and relatively low density. It has a distinctive silvery-gray color and exhibits minimal alteration when exposed to air. While some aluminum products feature surface coatings to enhance resistance, these coatings do not preclude the ability to create permanent dot peen and laser engravings.

Technomark specializes in producing laser and micro-percussion markings on aluminum components through specialized engraving techniques, all without altering the inherent properties of the parts, unlike chemical engraving methods.

These “ablation” engravings can range from superficial to deep (from 0.01mm to 2mm), and the renderings can appear light or dark, depending on the settings and the specific type of aluminum used.

We encourage you to share your marking and traceability project details with our experts, so that together we can define the best solution tailored to your unique needs.

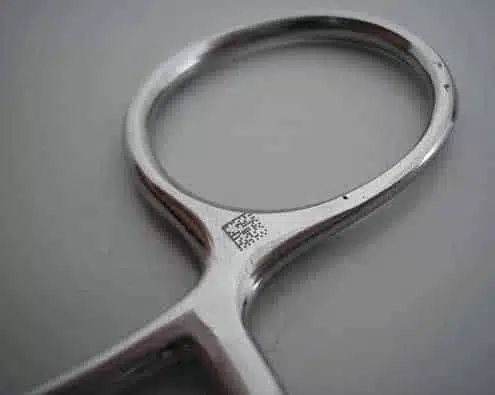

Stainless Steel Marking

Stainless steel is often used in sectors with stringent traceability requirements, such as the medical industry, where the majority of metal tools and utensils are made from this material. These tools need to be traced to monitor their usage and treatment, as sterilization procedures in this sector are particularly strict.

Stainless steel is renowned for its resistance to oxidation, corrosion, and deformation. The addition of chromium and nickel to the iron and carbon alloy enhances its oxidation resistance and mechanical properties. These exceptional qualities have made stainless steel an indispensable material across numerous industrial sectors.

Technomark specializes in marking stainless steel using laser or dot peen technology, without altering the properties of the components.