Blog

3 Solutions for Improving Manufacturing Traceability

3 Solutions for Improving Manufacturing Traceability In today’s competitive market, staying ahead means prioritizing traceability to ensure better quality, faster recalls, and smoother operations. From raw materials to final inspection, traceability ensures you know exactly where each component and material has come from and every step it took to reach the final product. But why […]

Types of Laser Marking: How to Choose the Best Laser for Your Needs

Choosing the right laser marking tool can be overwhelming, especially with the numerous laser technologies and marking options available. From fiber laser sources to CO₂ and green lasers, each has its strengths, and your choice directly impacts the quality of marking, material compatibility, and the long-term success of your operation. If you’re working in industrial […]

The XS Inline and GX Small: New Laser Marking Powerhouses

The XS Inline and GX Small: New Laser Marking Powerhouses Technomark is proud to offer two compact yet powerful laser marking solutions, the XS Inline and GX Small, designed to meet the evolving needs of modern production lines and standalone workstations. Whether you’re looking for seamless integration into your manufacturing line or a single-handed marking […]

Selecting Materials: Laser Marking Machine Guide

Selecting Materials: Guide for Laser Marking Machines Laser marking machines are necessary in sectors where labels must withstand tough conditions and stay readable. When picking the right laser for the job, it really boils down to the materials you’re working with. Whether you’re dealing with hard metals that demand precise, enduring marks or softer materials […]

Intro to Integrating Traceability Software for Manufacturing

Imagine having the ability to track every component, process, and product in your manufacturing chain with precision. TA traceability software enables manufacturers to navigate the complexities and regulatory requirements of modern production. Whether you’re a manufacturing manager, an operations director, or a quality control specialist, software traceability for manufacturing transforms how you manage your processes […]

Direct Part Marking 101 | Understanding Medical Part Marking Requirements

Over the past few years, there has been a significant shift in how medical devices are identified. Starting September 24, 2022, FDA regulations have required medical part marking through UDI direct marks on “any reusable and reprocessed medical devices on the U.S. market.” Many manufacturers have adopted Automatic Identification and Data Capture (AIDC) technologies to […]

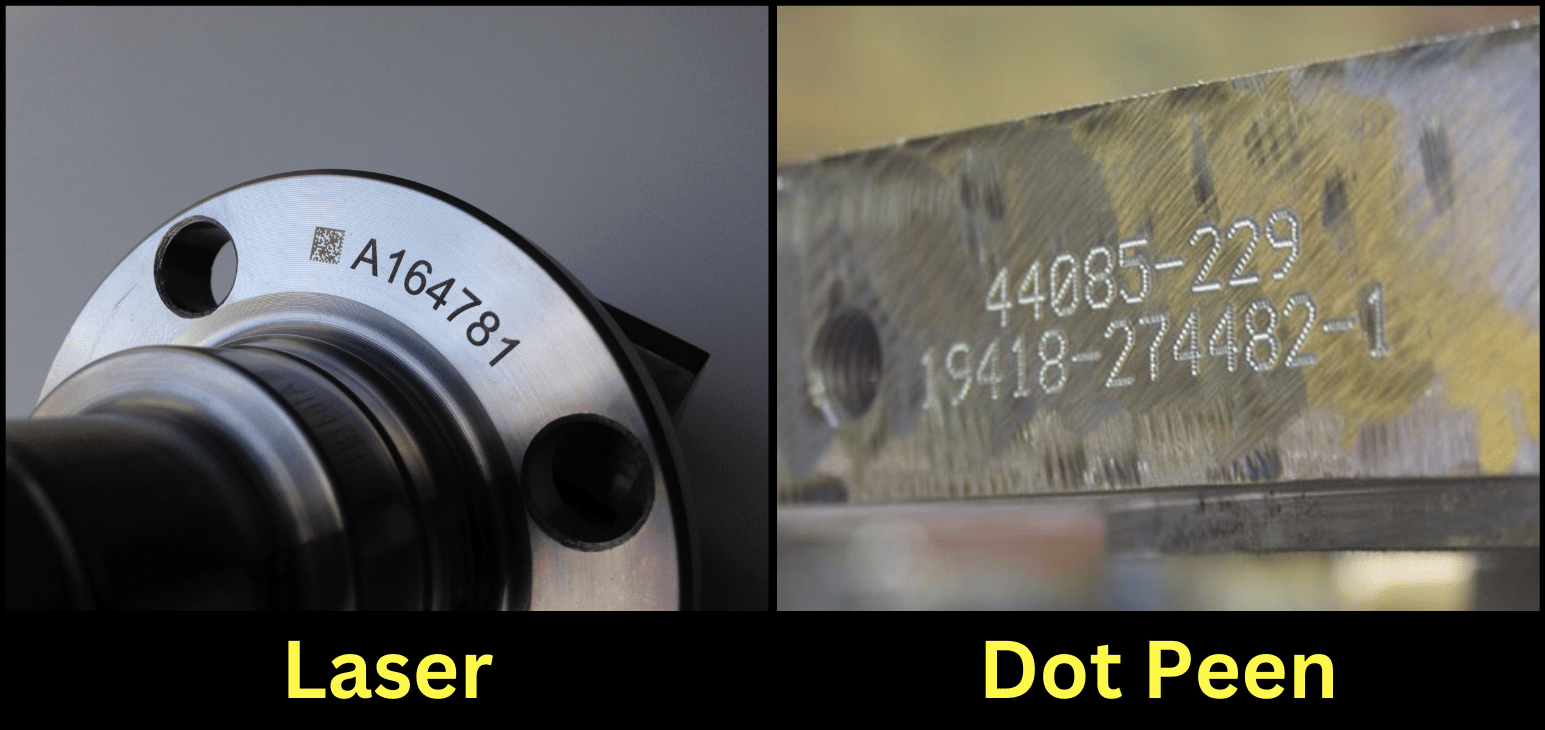

Laser vs Dot Peen Marking Machines: Direct Part Marking By Industry

When every part counts, every mark matters. In industries where traceability, compliance, and durability are non-negotiable, direct part marking ensures critical information stays where it belongs — on the part itself. Whether you’re tracking components through a supply chain, meeting regulatory standards, or branding products for longevity, the right marking method can make all […]

7 Benefits of Fiber Laser Marking Machines

Is your production line bogged down by outdated direct part marking methods? Imagine achieving clean, permanent markings on your parts with unmatched speed and precision — all while reducing maintenance headaches and boosting productivity. That’s the promise of fiber laser marking technology. Fiber laser technology has become a pivotal tool across industries because of its […]

Traceability in Manufacturing: 10 Part Marking Machine Considerations

Every part tells a story. In manufacturing, that story is written with precision and permanence. From serial numbers to intricate barcodes, part markings ensure every component can be identified, traced, and trusted throughout its lifecycle. But how do you choose the right system to deliver these critical marks?

4 Laser Marking Safety Best Practices

Laser marking is a valuable technology that has revolutionized product labeling and customization. However, like any powerful tool, lasers can be dangerous if not handled with care. Just as you wouldn’t give a chainsaw to someone without proper training, you shouldn’t use a laser without understanding its potential risks. From relatively harmless Class 1 lasers […]