Laser Marking and Industrial Traceability Solutions

High-Performance Laser Marking Solutions for Industry

Technomark offers advanced laser marking solutions designed to meet the highest standards of precision and reliability. Our laser marking machines are built to handle various industrial applications, ensuring clear, permanent marks on metals, plastics, ceramics, and more.

Why Choose Technomark Laser Marking Machines?

Technomark provides laser engraving and marking solutions designed for easy integration into any production environment, from compact workshops to large-scale manufacturing facilities. Featuring ergonomic designs and fiber laser technology, these laser marking machines offer fast, precise marks on metals and non-metals. Ideal for industrial marking systems, they support deep and light engraving for part traceability, decoration, and identification. Optional features like a 360° rotating axis enable versatile marking in all positions, making Technomark’s laser marking systems adaptable and efficient for any application.

Our laser marking systems provide superior traceability for industries like:

- Automotive

- Aerospace

- Medical

- Electronics

- Energy

- Defense

These systems guarantee permanent marks, offering flexibility in production environments with workstations and integrated options. Our solutions are designed for speed, durability, and versatility.

Our automated marking solutions:

- Deliver exceptional aesthetics: Precise and refined marking, ensuring visually appealing results.

- Handle diverse materials: Capable of marking on a wide range of surfaces, from metals to plastics.

- Offer flexible integration: Designed for both stationary and integrated use, adapting to various production environments.

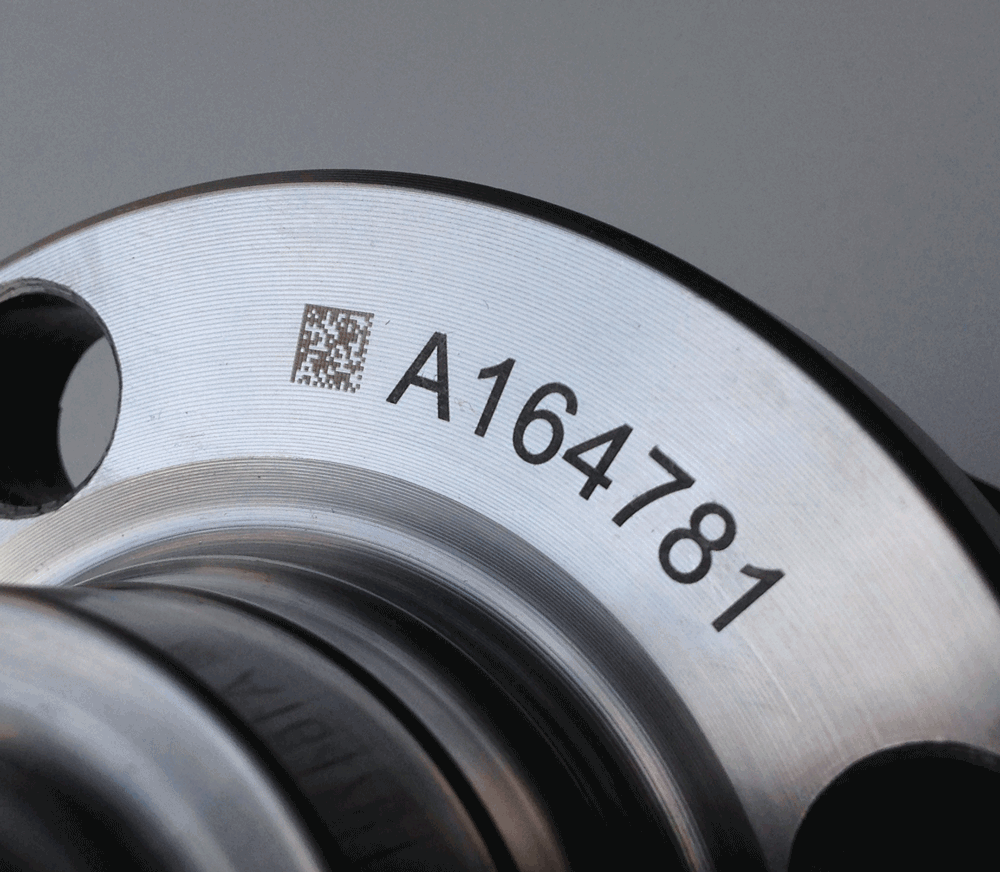

Enable versatile marking: Support a variety of marking options, including variable text, logos, and 2D barcodes (Datamatrix).

Reach out to us today to discuss your laser marking needs!

Our Industrial Laser Marking Solutions

Ultra compact

Ultra compact Fiber laser heads

Fiber laser heads Remote controlled

Remote controlled

GX Small Compact Laser Marking Station

Simple, precise installation

Simple, precise installation Standalone operation

Standalone operationSoftware with advanced features

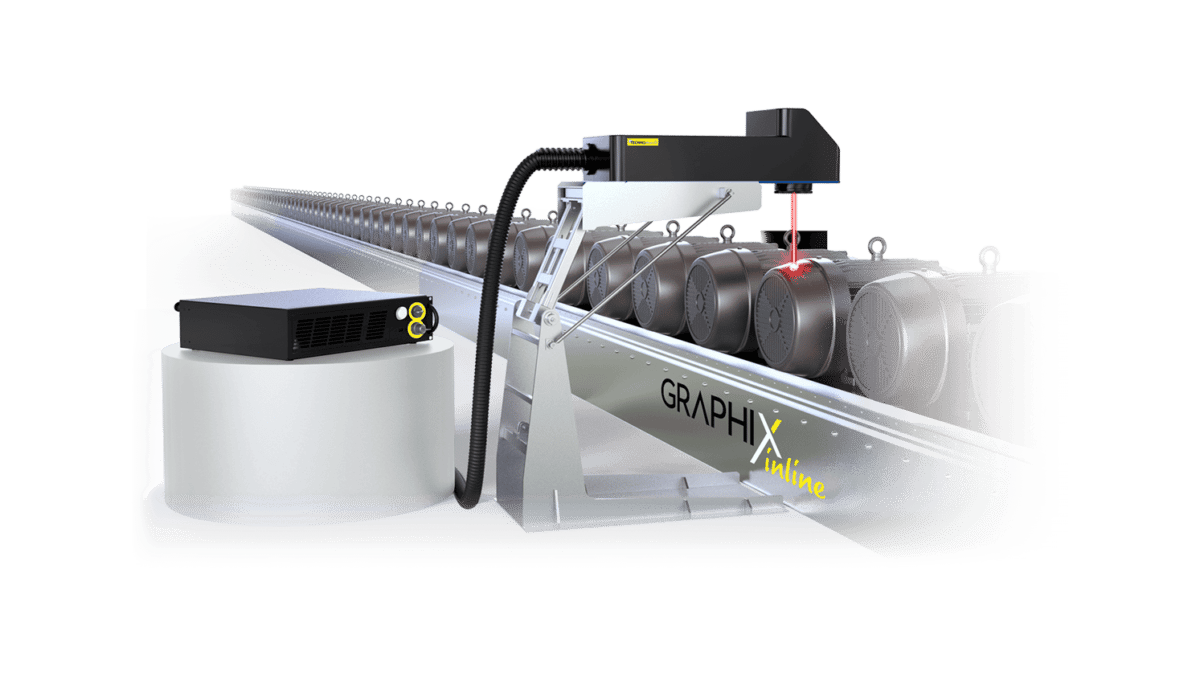

XS Inline Compact Integrated Fiber Laser Marking Head

Smart view function

Material database

Multi-level marking

Graphix Plus Laser Marking Station

The Graphix Plus is an all-in-one laser marking station for small to medium-sized parts. It features a motorized door, a large side opening for easy loading and unloading, an on-board camera for precise part placement, and intuitive software with a 3-click marking configuration. With these features, Graphix Plus simplifies the marking process and improves usability. Additionally, it offers multi-level marking for uneven surfaces and a wide range of accessories, including a rotating axis, adjustable keyboard support, and a smoke extractor. The Graphix Plus is available in 20W and 30W power options.

Reduced part stress

1D & 2D Code Marking

Powerful Interface

Graphix E-Series Integrated Laser Machine

The Graphix E-Series is a high-performance laser marking machine designed for seamless integration into production lines. With options for both deep and shallow marking, it is ideal for medium to large-scale industrial marking solutions. The system offers flexibility with multiple focal lens options and supports precise 1D and 2D code marking, making it an excellent choice for applications requiring industrial laser marking and automated marking solutions. The embedded PC simplifies setup, reducing the need for additional hardware.

What is Industrial Laser Marking?

Industrial laser marking is a non-contact, high-precision process used to create permanent marks on various materials like:

- Metals

- Plastics

- Ceramics

Laser marking systems use a focused laser beam, controlled by a galvanometric head with mirrors, to inscribe detailed information such as serial numbers, barcodes, and logos for traceability and product identification. This versatile technology is used in industrial marking systems for applications ensuring consistency and durability even in challenging production environments.

TECHNOMARK SOLUTIONS

Which Laser Marking Solution Is Right For You?

Integrated use

The integrated laser marking equipment enables extremely fast and high-quality marking on a wide variety of materials. By its compactness, its integration is easily facilitated into your production lines. Discover our laser solution dedicated to this integrated use.

Workstation use

The laser marking station can easily be installed in a workshop thanks to its adapted ergonomics and reduced size. Discover our laser solution

dedicated to this workstation use.

Discover Examples of Our Laser Marking Applications

Find & contact us

in the USA

Technomark North America 13626 Poplar Circle, Suite 502 Conroe, TX 77304 Tel : (888) 610-0151 – Fax : (936) 230-5679

info@technomark-inc.com

Find & contact us

in France

1 allée du développement

42350 La Talaudière

Tel : +33 (0)4 77 22 25 91 – Fax : +33 (0)4 77 22 38 93

info@technomark-marking.com

Find & contact us

in China, Asia Pacific & India

泰刻码标识设备贸易(上海)有限公司

上海市宝山区蕰川路512号 4幢 5层F座

邮编: 201906

办公室: 021 5108 6831 – 传真: 021 5121 1670

sales@technomark-marking.cn