What Is Dot Peen Marking?

What Is Dot Peen Marking and How Is It Used?

In industrial manufacturing, it’s key to track every component, especially when producing large volumes. The way you mark your parts is important, especially if they have to go through tough conditions or complicated supply chains. While there are many ways to mark industrial parts, dot peen marking has been a reliable choice for years.

So, why do so many people still prefer it? And is it the right solution for your production line?

Basically, dot peen marking uses a stylus that quickly taps onto a part’s surface, creating marks. This makes permanent, easy-to-read codes without damaging the material.

One common headache for manufacturers is having tools that can’t adapt. Production lines evolve, and switching from manual to automated systems can get expensive if you have to replace all your equipment. A big plus for dot peen marking is how flexible it is. It works whether you have a small manual workshop or a fully automated factory.

Thanks to their modular design, you can start with portable dot peen marking systems and later integrate them into your production line as your business grows.

Why is Component Traceability Important?

Before diving into the mechanics of dot peen marking, we must address the “why.” In today’s regulatory environment, component traceability is non-negotiable.

ISO standards and industry-specific regulations (such as AS9100 in aerospace or API Q1 in oil and gas) demand that parts be traceable throughout their lifecycle. If a valve fails on an oil rig, the manufacturer must be able to trace that specific component back to its production batch, material source, and date of manufacture.

Effective industrial part marking ensures this data travels with the part forever. Unlike stickers that peel off or ink that fades, direct part marking (DPM) creates a permanent record. This is where dot peen marking excels. By implementing robust component traceability protocols using dot peen machines, businesses protect themselves against liability and ensure rigorous quality control.

What is Dot Peen Marking?

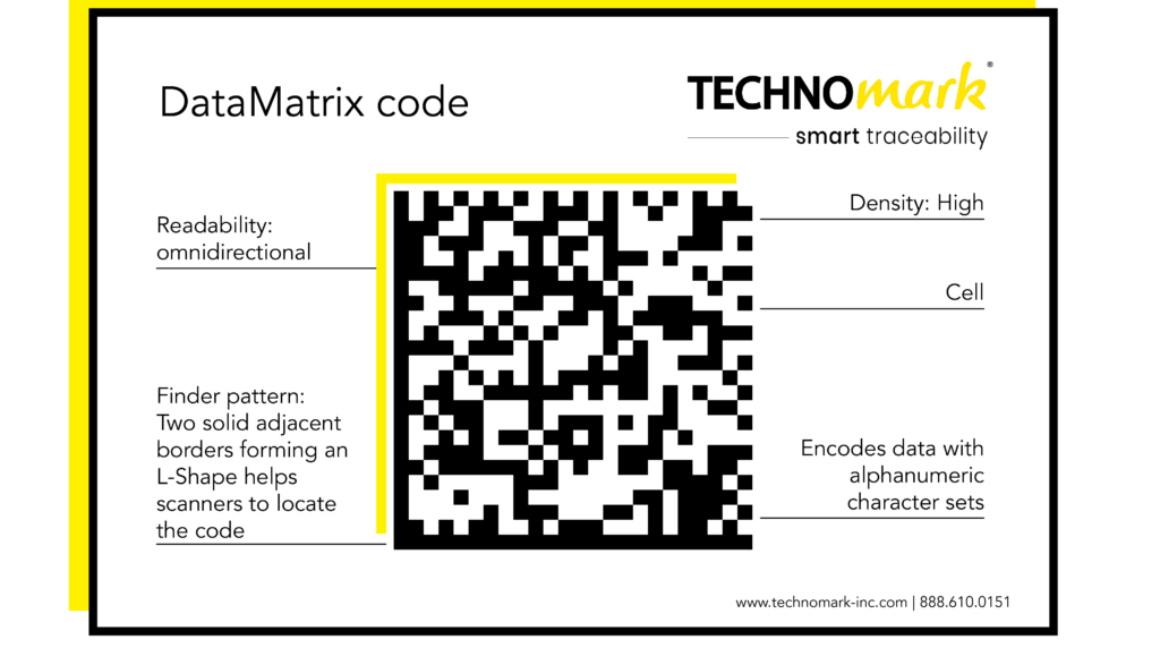

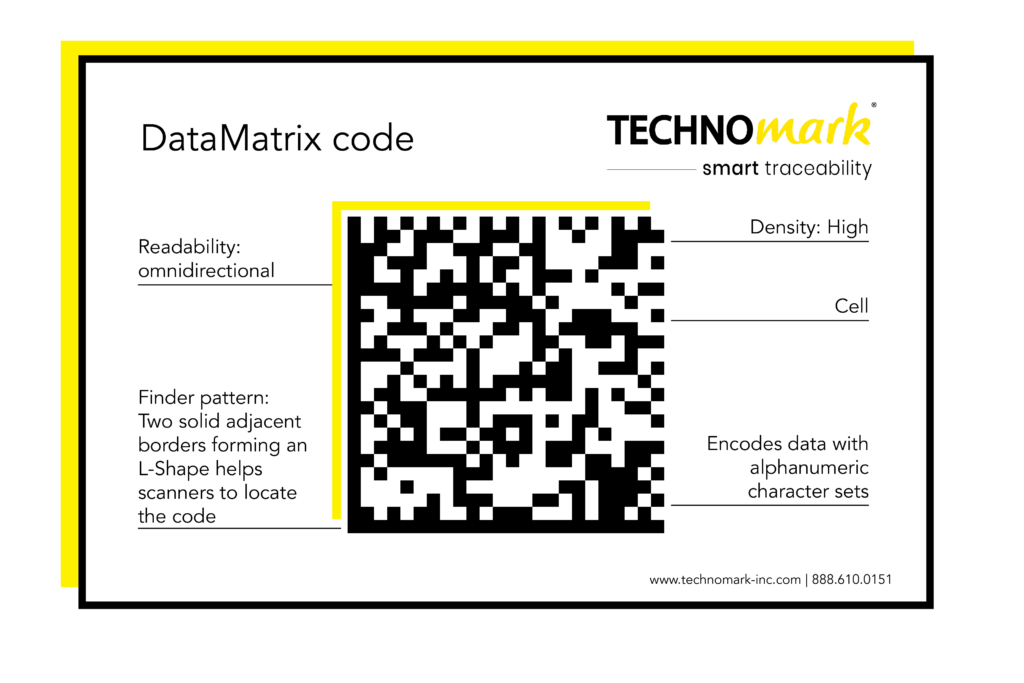

At a high level, dot peen marking is a method of direct part marking that uses an oscillating stylus to indent a series of dots into a material, creating human-readable text, serial numbers, or Data Matrix codes.

How It Works

If you were to disassemble a dot peen marking machine, you would find a stylus tipped with carbide or diamond. Driven by either electromagnetic solenoids or pneumatic force, this stylus strikes the surface of the part rapidly. The dot peen marking machine plots these dots on an X/Y plane via electronic control, ensuring precise alignment and depth.

The result is a permanent, legible mark. Because dot peen marking relies on material displacement (pushing metal aside) rather than material removal (cutting or burning), it is considered a “low-stress” marking method. This distinction is important for industries where structural integrity cannot be compromised.

The Versatility of Dot Peen Machines

One of the primary reasons manufacturers choose dot peen machines is their adaptability. Industrial part marking isn’t “one size fits all,” and dot peen marking technology reflects that.

Material Compatibility

A dot peen marking machine can handle a vast array of materials. From plastics to hardened steel (up to 63 HRC), dot peen marking is effective on almost any substrate used in heavy industry.

Form Factor Flexibility

The hardware comes in various configurations to suit different workflows:

- Benchtop systems: Ideal for small parts brought to a station.

- Integrated systems: Designed to be bolted into an automated production line.

- Portable dot peen marking systems: These are crucial for marking large, heavy, or immobile assets.

Explore more of our industrial dot peen marking solutions here

Portable dot peen marking systems have revolutionized field operations. Instead of moving a heavy steel pipe to a marking station, an operator can carry the machine to the pipe. This flexibility makes portable dot peen marking systems a favorite in the oil and gas sector and for inventory management in large warehouses.

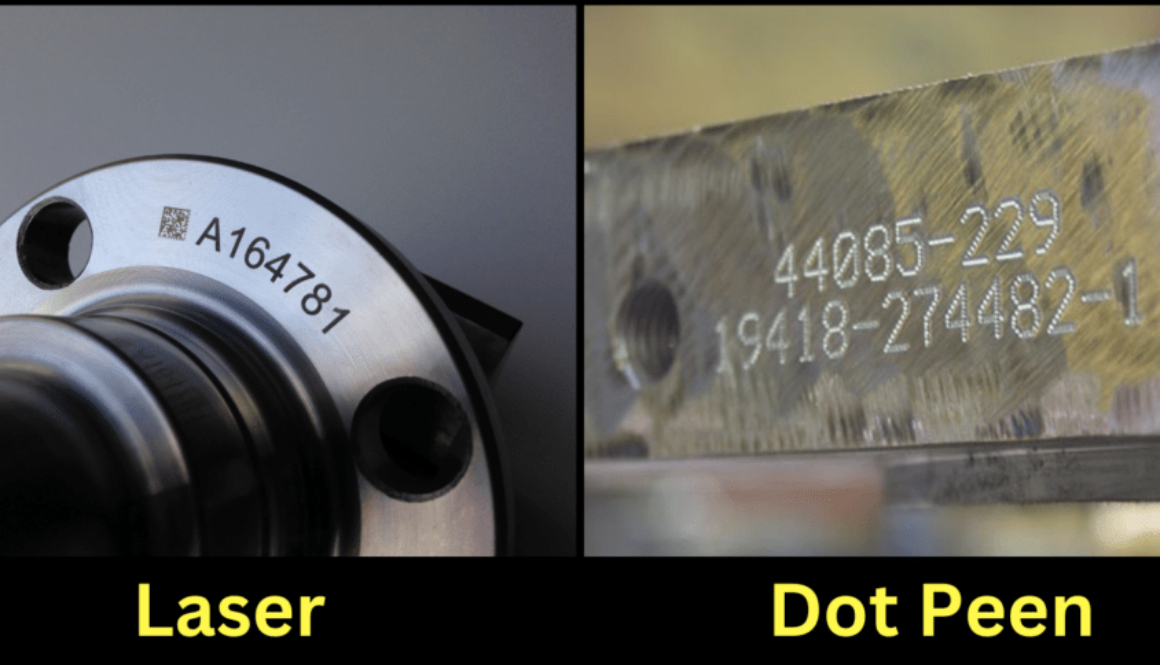

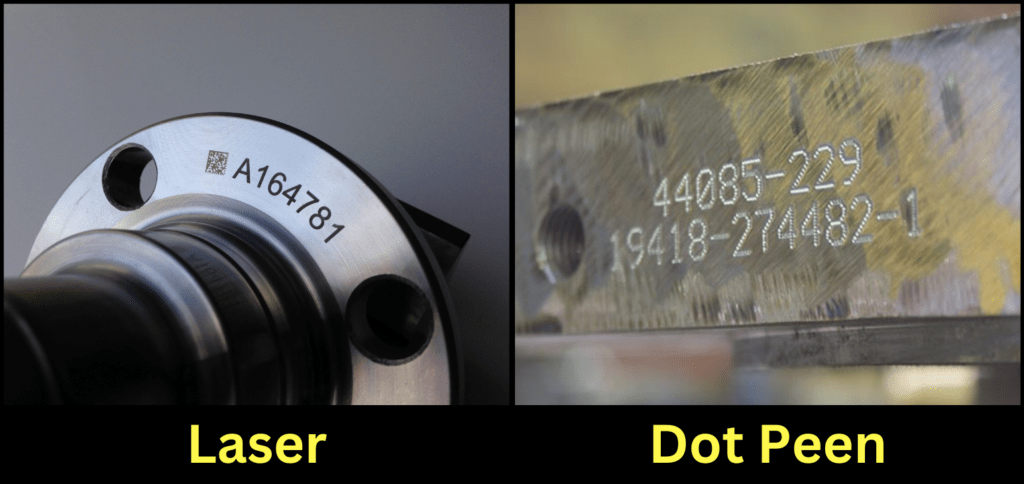

Why Choose Dot Peen Over Laser or Chemical Etching?

When evaluating industrial part marking solutions, buyers often compare dot peen machines against laser systems or chemical etching.

Here is why dot peen marking often wins:

Cost-Effectiveness

Laser systems can be prohibitively expensive to purchase and maintain. A dot peen marking machine is typically much more economical, often costing less than $10,000. For businesses looking to improve component traceability without blowing the budget, dot peen machines may offer a faster ROI.

Durability in Harsh Environments

Chemical etching can fade, and shallow laser marks can be painted over or sandblasted away. Dot peen marking creates a physical indentation. Even if the part is painted, galvanized, or subjected to harsh weather, the mark remains legible. This permanence is essential for long-term component traceability.

No Thermal Shock

Laser marking uses heat, which can alter the chemical structure of the metal (the heat-affected zone). In aerospace or high-pressure applications, this thermal shock can create weak points. Dot peen marking is a cold process. It induces no thermal shock, preserving the part’s engineering properties.

Dot Peen Applications in Industry

Dot peen marking machine technology is ubiquitous across several key sectors where industrial part marking is mandatory.

Oil and Gas

Valves, flanges, and tubular products are exposed to extreme pressure and corrosive environments. Portable dot peen marking systems allow operators to mark these heavy components right in the yard. The deep marks created by dot peen machines ensure that even after years of use in the field, the component traceability data remains intact.

Aerospace

The aerospace industry has the strictest requirements for industrial part marking. Because safety is of the utmost importance, parts cannot be subjected to stress risers or heat damage. The low-stress nature of dot peen marking makes it the approved standard for engine components, landing gear, and structural elements.

Automotive

Automotive manufacturers use dot peen machines for Vehicle Identification Numbers (VINs) on chassis and engine blocks. These lines are often fully automated. However, repair shops and custom builders frequently utilize portable dot peen marking systems for aftermarket parts or engine rebuilds, ensuring compliant component traceability.

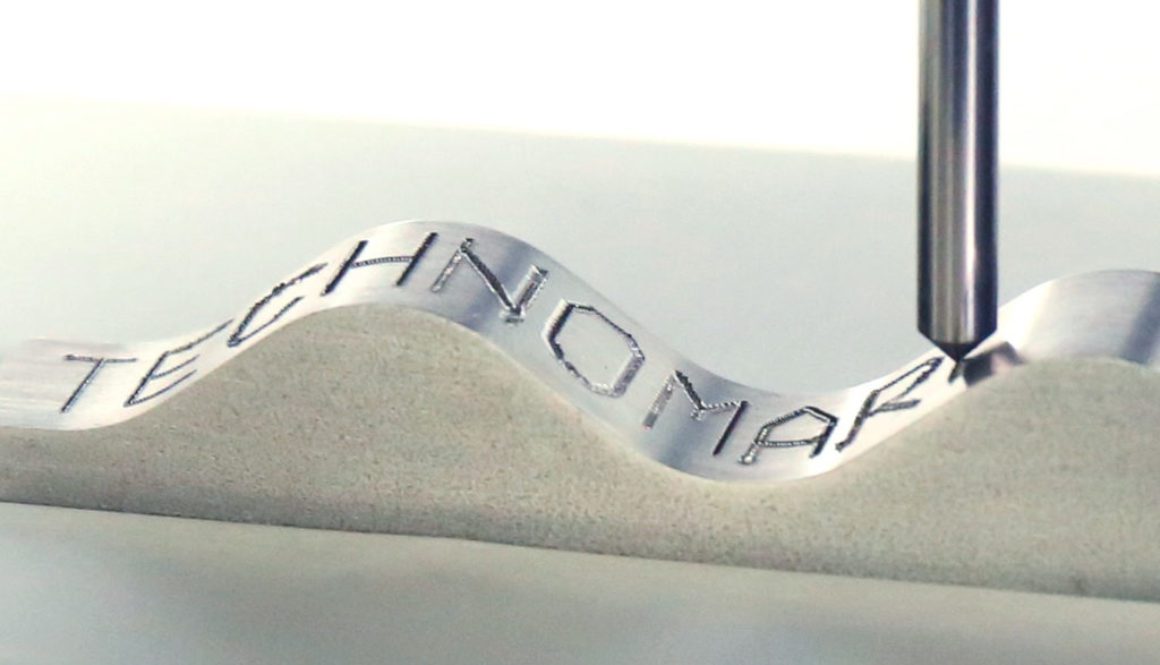

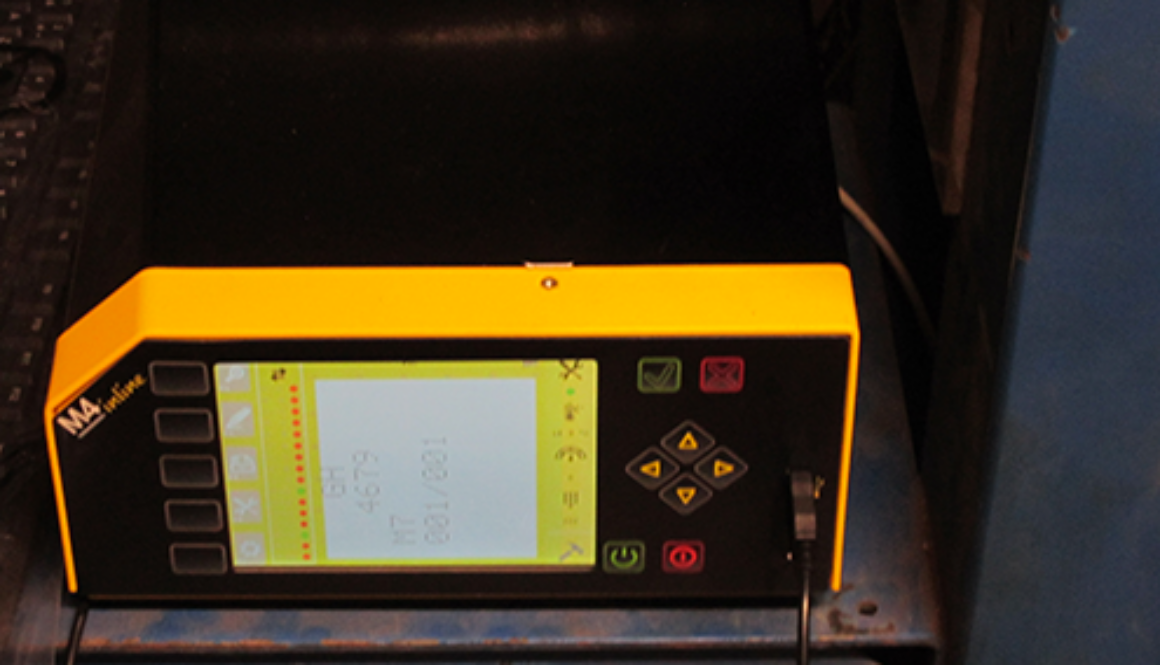

Advanced Features: Intelligent Driving Impact (IDI)

Not all dot peen machines are created equal. Advanced dot peen marking solutions feature Intelligent Driving Impact (IDI) technology.

In standard industrial part marking, marking a curved or uneven surface can be a nightmare. The stylus might miss the surface or strike too shallowly. IDI technology solves this by automatically adjusting the stylus level to the workpiece. Whether the part is flat, wavy, or curved, the dot peen marking machine maintains a constant depth.

This ensures high-quality component traceability marks regardless of the part’s geometry, significantly reducing the scrap rate caused by bad marks.

Integration and Mobility

The modern factory floor is dynamic. You need equipment that moves with you.

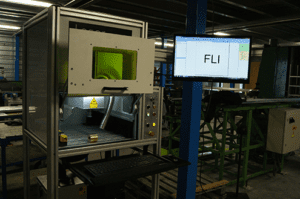

Automation Ready

For high-volume manufacturers, integrating a dot peen marking machine into an automated line is simple. These dot peen machines can communicate with PLCs to receive data automatically, ensuring the right serial number goes on the right part without human intervention.

The Power of Portability

For scenarios where automation isn’t possible, portable dot peen marking systems are the answer. Powered by high-capacity batteries, these units do not require compressed air lines or power cords. An operator can walk through a facility, applying industrial part marking codes to inventory on the fly. This mobility is a massive efficiency booster for component traceability audits.

Many portable dot peen marking systems are also modular. You can buy a portable unit today and convert it into a benchtop system later, providing ultimate flexibility for your growing business.

Future-Proofing Your Traceability

Component traceability is not just a box to check; it is a strategic advantage. It protects your brand, ensures compliance, and improves operational efficiency.

By investing in dot peen marking, you are choosing a solution that is durable, versatile, and cost-effective. Whether you need the brute strength of a benchtop unit or the flexibility of portable dot peen marking systems, there is a configuration to meet your needs.

Partner with Technomark for Uninterrupted Operations

Don’t let poor industrial part marking become a bottleneck in your production. If you have questions regarding dot peen machines or how to integrate a dot peen marking machine into your workflow, contact us today. At Technomark North America, we have the experience to help you get the best solutions for your industrial marking needs.

(Editor’s Note: This blog was originally published in September 2021 and was updated in December 2025.)

Data Matrix codes are another type of two-dimensional barcode, but they are smaller and more compact than QR codes. They are often used in industrial settings, such as manufacturing and logistics, because they are highly durable and can be scanned even when damaged or dirty. Data Matrix codes are useful for tracking individual items or components throughout production, ensuring accuracy and efficiency.

Data Matrix codes are another type of two-dimensional barcode, but they are smaller and more compact than QR codes. They are often used in industrial settings, such as manufacturing and logistics, because they are highly durable and can be scanned even when damaged or dirty. Data Matrix codes are useful for tracking individual items or components throughout production, ensuring accuracy and efficiency.

Laser marking wins in precision and detail, making it preferable for industries requiring intricate designs or small text. It is considered ideal for barcodes, UID codes, QR codes, and detailed logos.

Laser marking wins in precision and detail, making it preferable for industries requiring intricate designs or small text. It is considered ideal for barcodes, UID codes, QR codes, and detailed logos.