Manufacturing Traceability Solutions: What Are The Options?

Anyone who works in manufacturing, whether it’s automotive parts, aerospace components, or oil and gas equipment, knows that proper traceability is a cornerstone of product success. Clear, permanent identification ensures that every component can be tracked from production to end use, protecting both the manufacturer and the customer.

Having identification information on your components isn’t just useful for inventory management, quality control, and routine maintenance. It’s also often a federal requirement designed to uphold safety and compliance standards across industries. Without reliable part marking, recalls become more complicated, supply chains lose visibility, and regulatory audits grow riskier.

That’s why finding the right traceability method is so important. Manufacturers today have access to a wide range of direct part marking (DPM) solutions, each with unique strengths depending on the application. Some methods offer speed and flexibility, while others are designed for maximum durability in harsh environments.

The question is: which one fits your operation best?

Here’s the rundown of today’s most effective manufacturing traceability solutions for permanent identification.

Which Manufacturing Traceability Solution Is Best for You?

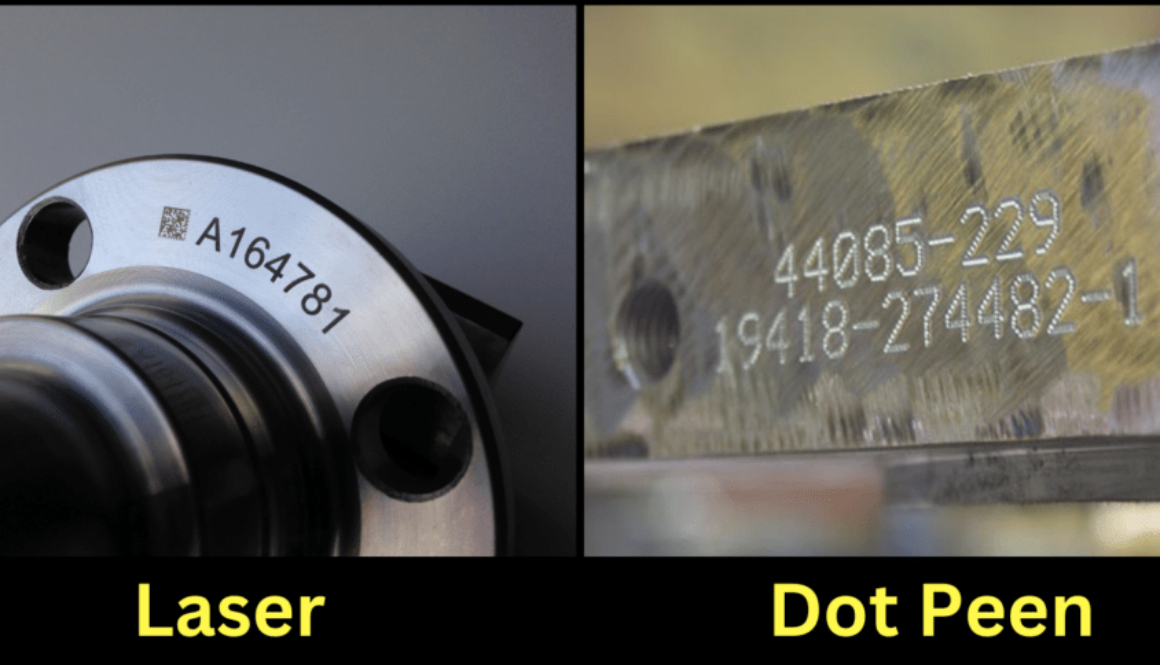

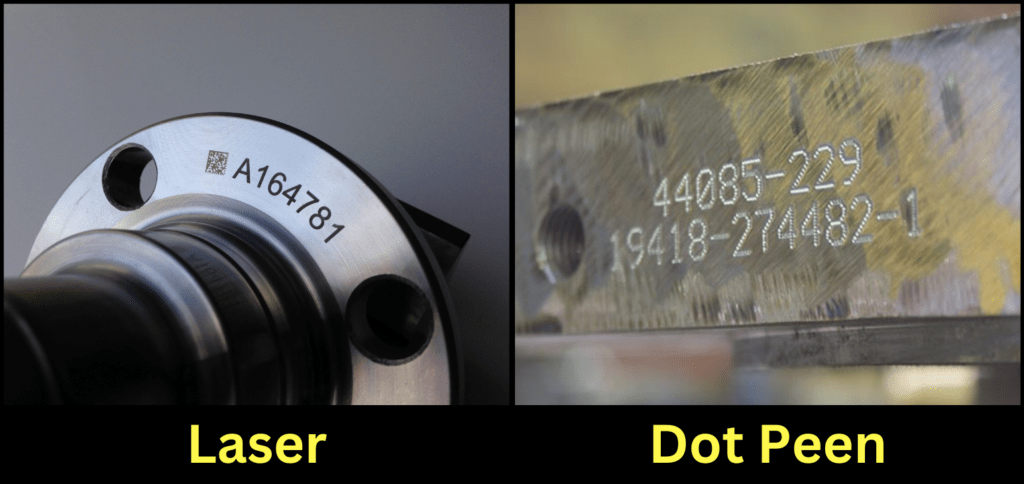

The ideal traceability solution for you will depend on your industry, processes, and applications. For example, delicate components like solar panels will benefit from laser marking, while other heavy-duty parts can use dot peen marking.

At the end of the day, the goal is to provide permanent and legible marking. Some of the most well-known methods include:

- Dot peen marking

- Laser marking

- Inkjet marking

- Impact presses

- Chemical etching

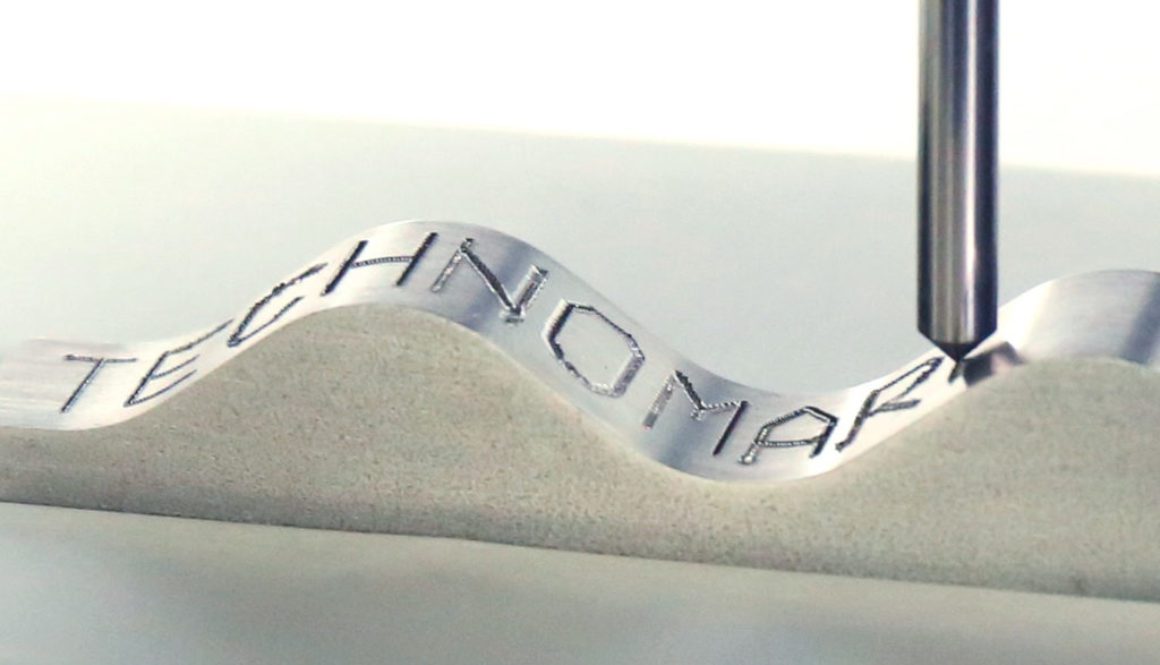

Dot Peen Marking

Dot peen is a direct part marking method, meaning that the marking head of the machine interacts directly with the component to achieve a permanent mark that can survive harsh operating environments.

Dot peen machines use an impact stylus to create small indents on a part’s surface to create letters, numbers, logos, or 2D datamatrix codes. Because the mark is formed via material displacement instead of material removal, it is considered a low-stress marking technique ideal for aerospace as well as oil and gas applications.

This method of marking is compatible with complete automation. The marking head can be integrated inline for high-volume production lines and requires minimal operator intervention.

Dot peen marking equipment is also well-suited to manual marking operations.. It can mark large or hard-to-reach parts, especially if you’re using a hand-held dot peen machine. Plus, dot peen is compatible with a wide range of metal materials, including steel, iron, and aluminum.

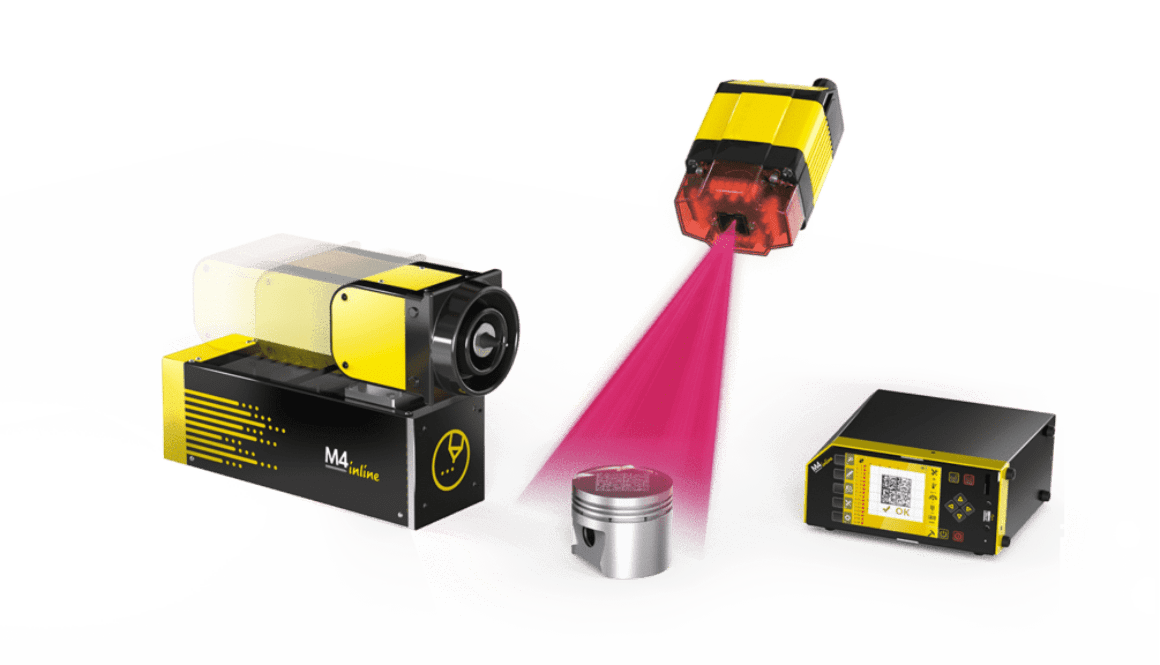

Laser Marking

Laser marking is one of the most widely used manufacturing traceability solutions because of its versatility. The mark is achieved by super-heating the part surface to etch, ablate, or anneal the material substrate. Target applications that are ideal for laser marking include:

- Wide range of plastics

- Ferrous and non-ferrous metals

- Elastomer compounds

- Organic materials (like wood or cardstock)

The laser marking system is ideal for high- or low-volume production, capable of marking high-quality 2D datamatrix barcodes and alphanumeric text to logos and graphics.

Other benefits of laser marking include:

- Compact design

- Flexibility

- Advanced, yet simple programming

- Capable of full automation

- 3D part marking

- Solid state design

- No consumables cost

While dot peen marking requires the stylus to make contact with the product, laser marking is a non-contact traceability method. This makes laser better adapted to marking complex geometries or delicate materials.

Inkjet Marking

While dot peen and laser marking systems provide a permanent traceability solution, inkjet marking offers a semi-permanent solution.

Inkjet marking functions a lot like a regular printing machine — using drops of ink to mark information on a substrate. It’s often regarded as one of the fastest marking methods, and is capable of marking on:

- Wood

- Rubber

- Concrete

- Textiles

- Plastic

- Metal

The downfall of inkjet marking is that it’s only semi-permanent. High levels of wear and tear or exposure to harsh environmental conditions can wear away the marking. As such, inkjet marking is usually used for consumer goods packaging, where the mark only needs to survive the short life of the product.

Impact Press Marking

Just like dot peen marking, an impact marking press indents a material with the desired identification information. However, the methods are different.

Whereas dot peen marking uses a series of cold-stamped dots to mark text, 2D datamatrix codes, or logos into a material, the impact press uses a die to stamp the information instead.

The process is similar to a letterpress, where characters are arranged in a specific order and then stamped onto the substrate. But with impact marking, the tooling is applied with enough pressure to indent the material.

A mechanical impact punch is versatile, capable of performing other manufacturing operations like coining or bending materials. However, the process isn’t digital (meaning the information is not dynamic) and has higher tooling and maintenance costs than other methods of marking.

Chemical Etching

Chemical etching takes an entirely different approach to direct part marking. This method uses chemical compounds to remove materials from the marking surface through a process of electrolysis, creating the impression.

Chemical etching is an accelerated form of oxidation. A stencil is soaked in an electrolyte solution and applied to the material. A low-voltage electric current is then applied to the stencil to initiate the oxidation process.

Chemical etching requires several steps to prepare the part for marking, but it’s a cost-efficient and quick process. It’s also less invasive than other marking methods, making it ideal for thin-wall parts.

However, chemical etching, like the impact press, is not a digital process. The information on the stencils is fixed, so you’ll need unique stencils for each different marking. On the upside, the materials involved are low-cost. Chemical etching is ideal for low-volume applications such as prototyping.

This marking method is primarily used for metal substrates, such as steel, aluminum, or nickel alloys. If you’re looking for marking on plastic or rubber, laser marking might be a better option.

Finding the Right Direct Part Marking Method for Your Application

A lot hinges on proper identification for manufactured parts, so choosing the right marking method is critical for smooth operations. The right solution not only ensures long-term traceability and compliance with industry standards but also supports efficiency by reducing errors and rework.

Many DPM methods, such as dot peen and laser marking, can be customized to meet your exact requirements, whether you need high-speed marking, permanent traceability, or adaptability across diverse materials.

Why Choose Technomark for Direct Part Marking Solutions

At Technomark, we understand that no two manufacturing operations are alike. That’s why we design our dot peen and laser marking systems to be versatile, durable, and easy to integrate into your workflow.

Whether your application requires high-volume part serialization, deep marking for tough environments, or precision marking for medical and aerospace components, Technomark delivers a solution tailored to your needs.

(Editor’s Note: This article was originally published in October 2022 and was recently updated.)

Laser marking wins in precision and detail, making it preferable for industries requiring intricate designs or small text. It is considered ideal for barcodes, UID codes, QR codes, and detailed logos.

Laser marking wins in precision and detail, making it preferable for industries requiring intricate designs or small text. It is considered ideal for barcodes, UID codes, QR codes, and detailed logos.