The Ins & Outs of Industrial Laser Marking Machines

The Ins & Outs of Industrial Laser Marking Machines

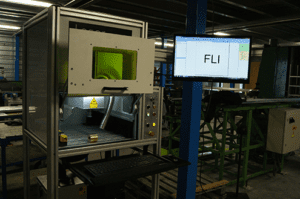

Industrial laser marking machines have become a trusted tool across many industries because of their ability to produce permanent, high-precision marks on a wide range of materials. From metals and plastics to specialized alloys, laser technology provides manufacturers with a consistent method for applying traceability information, product details, or even branding without physical contact or the need for additional consumables.

For companies considering this technology, the options can seem overwhelming. Different laser types, materials, and quality requirements all play a role in finding the right fit. Beyond the technical side, factors like throughput, integration with existing production lines, and long-term operating costs influence whether a machine will truly support a company’s goals.

This article explores how laser marking works, what sets it apart from traditional methods, and the considerations businesses should weigh when selecting equipment. Whether your priority is accuracy, durability, or efficiency, understanding the ins and outs of industrial laser marking machines can help guide a smarter decision for your operations.

Factors That Shape Results with Industrial Laser Marking Machines

To get a clearer picture of how laser marking delivers precise, lasting results, it’s worth looking at the elements that make up the process. Each factor, from the technology behind the laser to the characteristics of the material, directly affects performance and results.

A few important factors that make up this process include:

- Laser type: Different types of lasers are used for different types of marking applications. Generally speaking, a CO2 laser marking machine may be the best fit for plastics or polymers but not for stainless steel..

- Material: Different materials may require different laser parameters or even completely different types of lasers to achieve desired results. It’s important to consider the material’s properties before selecting a laser type.

- Quality requirements: The quality requirements of the applied mark determine which parameters must be considered during laser processing to ensure accuracy and precision.

Some common laser parameters include:

- Pulse rate

- Line width

- Speed

- Power density

- Dwell time (the amount of time the laser is applied to a single spot)

- Equipment used: Depending on your application needs there are many different kinds of industrial laser marking machines available on the market today – each with their own advantages and disadvantages that should be considered when making selection decisions.

Laser marking offers numerous advantages over traditional marking methods, including:

- Stamping

- Printing

- Engraving

Laser marking is a fast, accurate, and permanent process. It can also be used to mark a variety of materials without the need for additional setup or alteration. The laser beam never touches the material being marked, making it possible to achieve high-precision marks with no significant post-processing required.

These features make laser marking ideal for precision parts and items that require both high accuracy and long-lasting markings.

Key Considerations When Choosing a Machine

There are several factors related to the product line and marking requirements that must be considered when choosing a laser marking machine. Here we will dig a little deeper into some of those factors, including:

- Marking requirements and specifications

- Material compatibility

- Marking speed and throughput

- Maintenance and operational costs

- Integration with existing production line

- Safety considerations

1. Marking Requirements and Specifications

The marking requirements are important to consider when choosing among the options for high accuracy laser systems. The process should begin with an understanding of the specific needs of the product being marked, including its size, shape, material, and desired end result.

For example,

If a product requires detailed engraving that is outside of the capabilities of some machines, then a different option may need to be chosen.

Additionally, depending on the material being marked or engraved upon, different laser types may be more suitable than others in terms of speed and quality.

It’s also important to consider how frequently the machine will be used and how many products it needs to mark per hour or day.

This will determine not only which type of laser marking system is most suitable but also whether faster systems require higher maintenance costs. Considering these factors can help ensure that the right machine is selected for the job.

2. Material Compatibility

The right laser marking system should be compatible with the materials that need to be marked or engraved. Laser engraving on stone, glass, or metal requires different laser types and power settings.

For example,

A CO2 laser marking machine is suitable for engraving woods, plastics, and some metals, but might not be able to mark stainless steel perfectly due to its higher reflectivity.

On the other hand, fiber lasers are more suitable for metals such as aluminum, brass, and titanium due to their higher power output. Therefore, it’s important to consider which material needs to be marked or engraved before choosing a laser marking machine.

3. Marking Speed and Throughput

Faster laser machines can process more work in less time, allowing businesses to realize faster cycle times and higher throughput.

Moreover, higher throughput can also enable businesses to take on bigger jobs that require more items to be marked or engraved in shorter amounts of time.

For example,

If a business needs to engrave 1000 parts per day, it will need a laser marking machine with high speed and throughput to meet its daily production requirements.

4. Maintenance and Operational Costs

In addition to the other considerations when choosing a laser marking machine, businesses should also be aware of the associated maintenance and operational costs. Regular maintenance is key to keeping these machines in optimal condition, as well as ensuring safety during use.

Operational costs will vary depending on the type of material being marked or engraved, including energy consumption levels and safety requirements that must be met. Businesses may also find that an integrated laser marking machine reduces downtime by streamlining workflows and minimizing setup.

In some cases, the cost of consumables like lasers may also add up over time. To ensure that businesses get the most out of their investment, they should factor in all long-term operational costs when selecting a laser marking machine.

5. Integration with Existing Product Line

When integrating a laser marking machine into existing product lines, several factors must be taken into consideration.

The first consideration is whether a new machine is compatible with any existing product lines. An integrated laser marking machine makes it easier to maintain seamless communication with other systems in the production line. The potential for physical compatibility and system integration should be assessed before implementation.

Next, the safety of any operators or users must be taken into account to ensure they can use the machine safely.

The laser marking machine should also be equipped with any necessary features for seamless integration with other production processes or products. It is also essential to consider the cost-effectiveness of installing such a machine and assess how it will fit within current budgets and operational expenses.

6. Safety Considerations

Safety is an incredibly important factor when it comes to the implementation of laser marking machines. Not only should any potential machine be capable of providing safe conditions for operators, but it should also have advanced features such as motion sensors and emergency stop buttons to respond quickly in cases of unexpected events.

All machinery must conform to necessary safety standards and regulations, both from the local legislation and from any international or industry-specific standards. Manufacturers must also provide extensive safety information about their products, including a detailed user guide that helps users understand how to operate the machine safely.

Applications of Industrial Laser Marking Machines

Industrial laser marking machines are used to mark metal parts with information such as serial numbers or expiration dates. Permanent laser marking helps these industries maintain their standards of reliability while providing a cost-effective solution.

In addition to the technical requirements of accuracy and longevity, lasers can also be used for more decorative applications, such as engraving images or logos. Industrial laser machinery is becoming an increasingly important part of manufacturing processes in high-tech industries due to its versatility, cost efficiency, and ability to create precise, permanent markings.

The following industries require reliable laser marking solutions to ensure long-lasting performance and accuracy:

- Automotive

- Aerospace

- Electronics

- Medical

1. Automotive Industry

In automotive manufacturing, precision and accountability are central to production. Laser marking supports these needs by creating durable, high-contrast codes that streamline inventory management, strengthen quality control, and make it easier to trace defective parts back through the supply chain. Datamatrix codes, in particular, are widely used to encode detailed part information in a compact format, ensuring reliable readability during inspections or recalls.

Beyond critical components like braking discs, laser systems are also applied to plastics, such as housings and connectors, where permanent identification is required without compromising structural integrity. The combination of speed, permanence, and adaptability makes laser marking a valuable asset for meeting the demands of high-volume automotive production.

2. Aerospace Industry

Aerospace components must withstand demanding environments, making accurate identification and traceability essential for ensuring safety and compliance. Laser marking excels in this space, offering the ability to permanently mark metals such as titanium, steel, and aluminum without weakening the part. Alphanumeric codes and 2D DataMatrix markings allow for comprehensive part tracking, ensuring manufacturers and operators can verify each component’s origin and performance history.

A common application is marking turbine blades — an area where readability, resistance to wear, and long-term legibility are important for traceability purposes. By having consistent part identification, laser marking systems contribute to efficiency in maintenance, certification, and lifecycle management.

3. Electronics Industry

With increasingly compact and complex designs, the electronics industry relies on laser marking for precise component identification and brand protection. The technology allows manufacturers to place permanent, high-resolution marks on small surfaces without damaging delicate circuitry or altering material properties. This capability supports efficient inventory control, compliance with labeling regulations, and greater transparency in the supply chain.

Laser marking also helps safeguard brand integrity by making it more difficult for counterfeiters to replicate product markings. In electronics, a CO2 laser marking machine can be handy for marking connectors and casings made of plastic. Whether applied to plastic connectors, PCBs, or micro-components, laser systems deliver clarity and permanence that printed or adhesive labels cannot match.

4. Medical Device Industry

In healthcare, reliable product identification directly supports patient safety and regulatory compliance. Laser marking provides permanent, biocompatible markings on medical devices, ranging from surgical instruments to implants and even smaller items, such as pacifiers. These markings improve readability for product IDs and traceability, which is vital in monitoring device use, sterilization cycles, and recall situations.

The medical device industry also benefits from laser technology’s ability to produce marks without introducing contaminants or compromising device functionality. By enhancing traceability and supporting quality of care, laser marking aligns with the strict standards set by organizations such as the FDA and ISO.

Partner with Experts for Your Laser Marking Needs

Choosing the right industrial laser marking machines is about more than just comparing technical specifications — it’s about aligning the technology with your production goals, material requirements, and long-term operating needs. From the type of laser used to the way it integrates into your existing processes, each decision shapes the reliability, efficiency, and overall value of your investment.

With so many variables to consider, having an experienced partner can make the selection process far more straightforward.

Explore Laser Marking Solutions with Technomark

If you’re ready to explore your options further, our experts are available to answer your questions and help identify the right solution for your business. The team at Technomark understands the challenges manufacturers face and offers guidance tailored to your applications, whether you’re focused on traceability, throughput, or durability.

You can also access our free resource for a deeper dive into laser types and selection considerations.

(Editor’s Note: This article was originally published in August 2023 and was recently updated.)

Laser marking wins in precision and detail, making it preferable for industries requiring intricate designs or small text. It is considered ideal for barcodes, UID codes, QR codes, and detailed logos.

Laser marking wins in precision and detail, making it preferable for industries requiring intricate designs or small text. It is considered ideal for barcodes, UID codes, QR codes, and detailed logos.