Automotive Part Marking 101 | Component Traceability

The number of parts used to make a single car has doubled in the last 10 years. As cars get more complex, it’s harder to track parts through inventory, production, and the car’s entire life. More

The number of parts used to make a single car has doubled in the last 10 years. As cars get more complex, it’s harder to track parts through inventory, production, and the car’s entire life. More

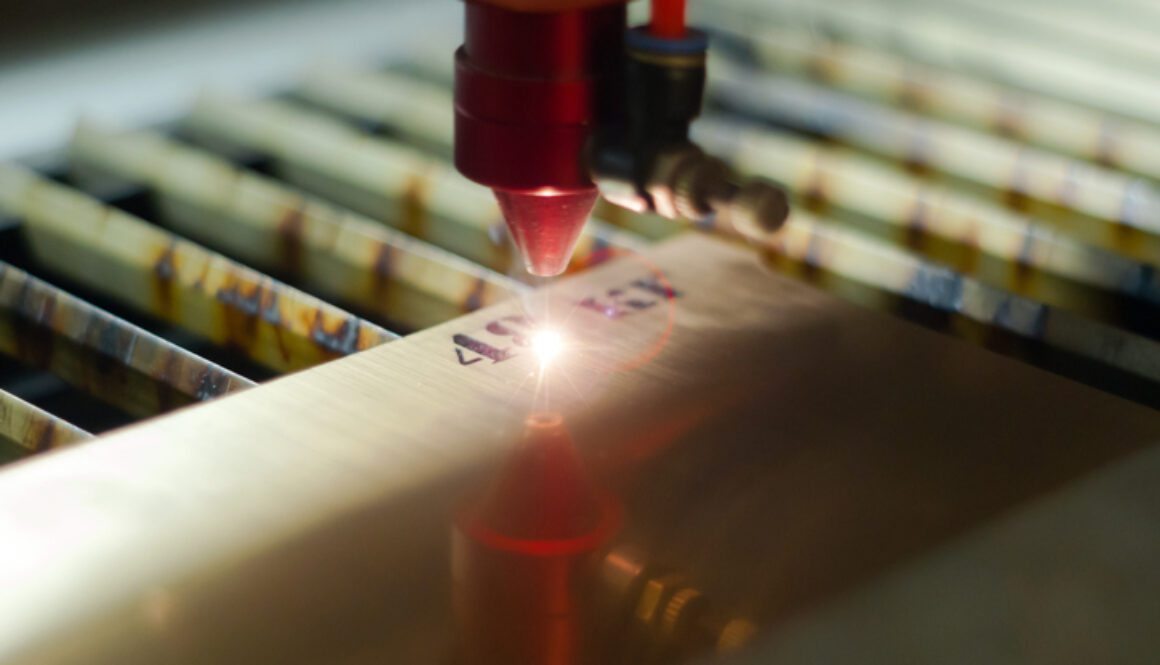

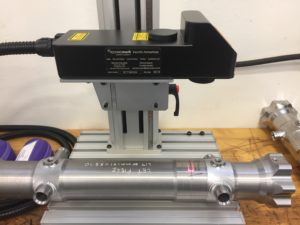

Customized part marking is essential for the successful production of parts in a variety of industries. By applying unique identifiers to each part or component, manufacturers can ensure precision in their production process while ensuring traceability throughout product life cycles. An industrial metal engraving machine provides that capability during the production process.

Part marking is also an essential tool for reducing waste and improving efficiency across a variety of sectors. In fact, the use of metal marking is vital to the production of more industries than you think.

The use of an industrial metal engraving machine is well worth the investment for a variety of industries, but the following six see particular advantages:

Aerospace part production demands a high degree of accuracy because of the extended exposure to high heat and vibrations, which can lead to part failure. As a result, customized part marking is necessary for the successful completion of parts that meet the strict requirements of the aerospace industry.

Metal marking machines also reduce waste and increase efficiency in production, as it allows for accurate identification of parts while not causing damage to the part surface. Aerospace part marking provides a unique identifier for each part produced, which can help ensure traceability throughout the entire aerospace product life cycle. Aerospace equipment is costly, which means proactively avoiding defects can make a difference in the profit margin.

Both dot peen and laser marking can be efficient methods of custom part marking for aerospace production.

Unique Device Identification (UDI) is a system of marking medical devices, such as pacemakers and artificial joints. UDI identifies and traces each device throughout all stages of its life cycle. It enables easy identification of specific product versions and lots, helping prevent mix-ups or recall issues in the case of a malfunction.

Part marking is essential for UDI compliance, as it ensures that all medical devices are traceable. Part marking machines for the medical industry can also apply:

The automotive industry relies heavily on part marking to catalog and traces each component throughout the production process and the vehicle’s life span.

Data matrix codes provide significant information in a small surface area and make it easier to read throughout the component’s useful life. Data matrix is:

Parts for the oil and gas industry must be marked with special techniques to ensure they’re identifiable both downhole and on the surface. This is critical, as oil and gas parts have a variety of components that will be exposed to high pressures and harsh environmental conditions. Therefore, permanent mark identification is required to ensure traceability and reduce liability in the event of a failure.

Part marking is also essential for safety, as it provides personnel with the information needed to ensure proper operation and maintenance of oil and gas parts. By applying customized part markers, manufacturers can make sure that the right type of parts are used in each application, reducing unnecessary risks and ensuring optimal performance.

Metal marking machines are also necessary for oil and gas parts to ensure they meet the requirements of their specific industry. These unique part markers can reduce waste in production, as they allow you to ID parts quickly and accurately without manual labor or additional equipment. This helps in reducing errors and improving efficiency.

In the electronics industry, part marking is essential for traceability and identifying counterfeit parts. By applying unique identifiers to each component, manufacturers can ensure that only genuine parts make it into their products.

QR codes are increasingly being used to identify electronic products in a number of industries. QR codes are 2D barcodes that can be scanned and read by a smartphone or other device.

In the electronics industry, QR codes can track components throughout the manufacturing process. They’re also used to store serial numbers, batch numbers, and expiration dates.

QR codes are also becoming increasingly popular for tracking electronics in the supply chain, as they allow companies to quickly and accurately identify products throughout their life cycle. This reduces the risk of product mix-ups and mislabeling, while helping to ensure that all products are safe and compliant with industry standards.

Custom part marking is an essential process in metalworking, where shops often have numerous orders and projects going on at once. By applying unique identifiers to each part, manufacturers can quickly and accurately identify the components they need for their various projects. This helps reduce waste in production, as it eliminates the possibility of errors and increases run speed.

Part marking is also essential for metalworking to ensure that end products meet industry standards and specifications.

Part marking systems for metalworking are typically laser- or ink jet-based, as these methods create permanent marks that won’t fade and become unreadable over time. Laser marking has the advantage of being more precise than traditional methods, and is usually the preferred choice when producing parts with tight tolerances.

Custom part marking is essential for the success of any production process, especially in mission-critical industries like aerospace, medical, automotive, oil and gas, electronics, and metalworking. By applying unique identifiers to each component or product being produced, manufacturers can ensure accuracy and traceability throughout their entire life cycle.

Additionally, customized part markers reduce wasteful errors caused by mislabeling or mix-ups. With the right custom marking system in place, businesses can work more quickly while still taking care to meet industry standards and regulations.

Metal marking machines are key to a variety of industries. Each use case is unique.

Take a look at other blog posts in our Direct Part Marking 101 series:

Medical Part Marking Standards Explained